The problem of fast-wearing elbows

The site reliability engineer was looking for a way to overcome the problem of his plant’s cyclone feed elbows wearing too fast in the milling area. The rubber-lined steel spools were only lasting 3-6 months, which was out of step with the plant’s shutdown schedule.

He needed a solution that was going to provide longer wear and better predict the lifespan of the piping.

Also, replacement parts were taking too long to arrive on site, so the team was making costly temporary repairs to reach each shutdown.

The plant processes 14,500 metric tonnes of ore each year, so ongoing breakdowns for such a large-scale mine is costly.

Getting to the bottom of it

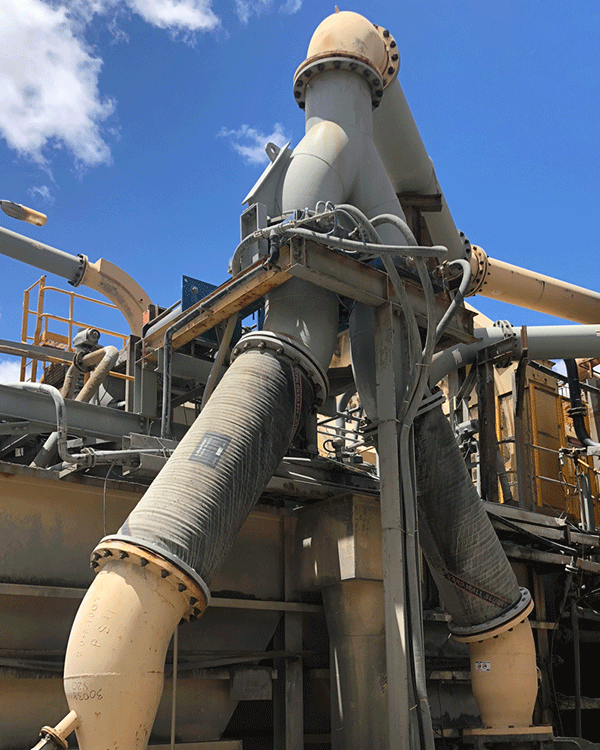

The reliability engineer invited us to site to inspect the pipework so we could understand their situation.

We could see that the tight piping geometry was causing isolated wear from particles hitting the outer radius of the elbows. Rubber-lined steel spools struggle to cope with impact absorption and tighter bends exacerbate the problem. This is one of the most common issues we see with cyclone feed elbows.

The maintenance team were finding it hard to gauge when they needed to replace the spools, which was leading to unplanned shutdowns.

We know how hard it is to make sure pipework in the milling area lasts the distance. It’s a critical area in any processing plant. We spend a lot of time on site working with customers to help them make the right decisions about what’s going to help their plant be more productive.

Our four recommendations

1. Re-engineer bends

Our piping specialists found that the elbow design with such a tight radius was causing unnecessary wear from high velocity particles in localised spots. Continuously replacing the elbows due to wear and leaks was also causing misalignment in the pipework. To overcome this, we redesigned the piping geometry with more sweeping bends. This would encourage a steadier flow of slurry and extend the lifespan of the pipework.

2. Address excessive impact absorption

To overcome the problem of excessive localised wear on the rubber-lined spools, we proposed that the team look at Slurryflex CLX pre-formed mining hose bends. An alternative to steel spools on cyclone feeds, mining hose can better handle impact and absorption. The CLX ceramic tile liner is deeply bonded in the manufacturing process using a vulcanisation process to provide extra wear resistance.

3. Introduce wear monitoring

To provide advance warning of when the pipework would fail, we suggested installing wear monitors on the bends. We build the monitors into the lining of the hose, with an indicator box fitted on the outside.

4. Improve inventory planning

To help with installation and maintenance, we suggested numbering each of the hoses. We’ve found that this helps maintenance teams reorder parts, and improves labour allocation during shutdowns.

Better days at Fimiston

The reliability engineer reviewed our report and decided to proceed with our recommendations. He ordered the pre-formed bends and wear monitor switch box.

The re-ordered replacement parts arrived onsite faster as they are all manufactured in Australia. Without delays due to parts getting stuck in port, there were fewer costly repairs in between shutdowns.

Two years on, the hoses are still going strong. The new mining hoses have lasted more than five times longer than the old rubber-lined spools. That means no leaks, and no unplanned shutdowns. And now the maintenance team can simply press a button and they’ll know when it needs to be replaced.

Lifespan 5x longer than rubber-lined

Durability No more bandaging leaks

Predictive maintenance Wear monitors improve shutdown planning

Custom made Engineered to specification