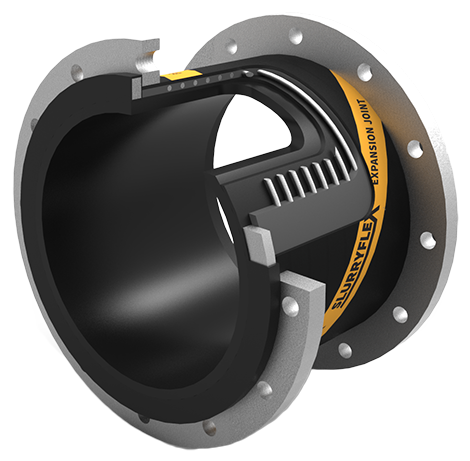

The Slurryflex SJD-Series Rubber Vibration Joint is designed to dampen vibration and reduce noise in slurry pipework. Having no arch, it has limited movement capability compared to expansion joints but similarly relieves stress and compensates for pipe misalignment.

Standard applications for the Slurryflex vibration joint are the transfer of abrasive slurries, sand, and gravel in mineral processing plants and tailings pipelines. It can also be customised for chemicals, acids, and hydrocarbons.

All of our Slurryflex expansion joints are custom made in Australia from premium materials. Tell us about your application and we’ll help you choose the right materials, size, length, and end connections.

Technical specifications

Brand

Slurryflex

Model

SJD-Series

Joint diameter

DN50–1500 (2–60”)

Contact us for larger sizes

Contact us for larger sizes

Joint lengths

Custom lengths to suit requirements

End connections

Fixed flange

Beaded end swivel flange

Double flange

Plain cut end

Beaded end swivel flange

Double flange

Plain cut end

Flange drillings

AS2129, ASME, BS, SABS, JIS, DIN, custom

Pressure rating

Up to 5000kPa as standard

Contact us for special requirements

Contact us for special requirements

Safety factor

4:1 for minimum burst pressure as standard

Contact us for special requirements

Contact us for special requirements

Temperature rating

-30°C to +75°C as standard

Contact us for special requirements

Contact us for special requirements

Material specifications

Inner liner

Slurryflex Grade-A Rubber, proprietary compound for wear performance in abrasive slurries (contact us for other specialty applications)

Outer cover

Proprietary rubber compound for UV, ozone, and abrasion resistance

End connections

Carbon steel (painted, galvanised, custom)

Stainless steel (SS304, SS316)

Exotic alloy (on request)

Stainless steel (SS304, SS316)

Exotic alloy (on request)