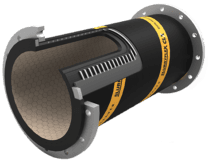

Slurryflex. The World's Toughest Mining Hose.

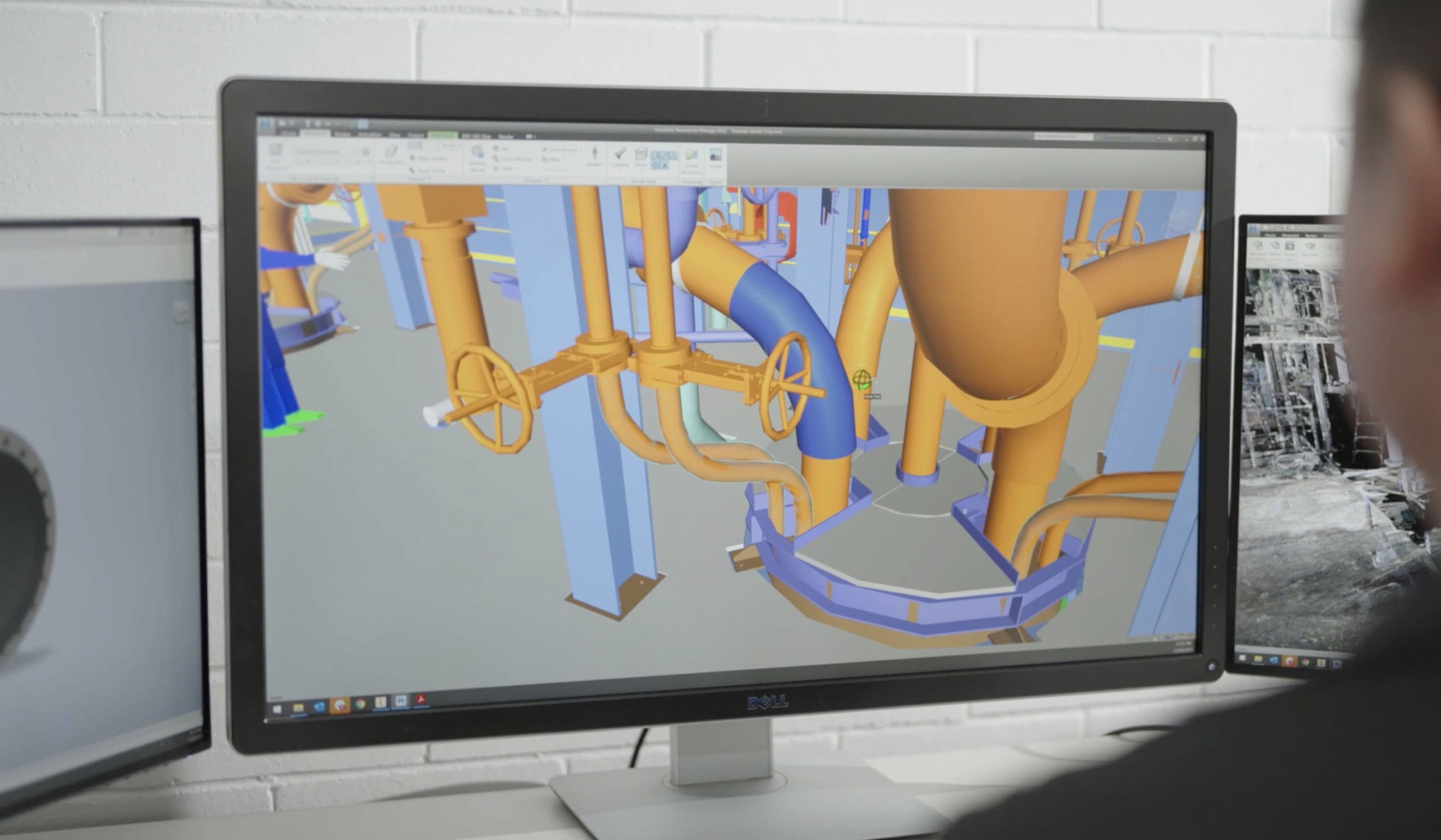

How it's made—watch the video

Slurryflex lasts longer, so you can stop bandaging leaking pipes and focus on other areas of the plant.

Why does it last longer? Because each hose is made to our proprietary designs by our skilled manufacturing team using our high-performance rubber compounds.

You can be sure that every hose you get will be as reliable as the last one. That’s because more than 15 quality checks go into every Slurryflex mining hose. You get a consistently high-quality mining hose backed up by ISO:9001 certification and 100% Australian manufacturing.

Watch the video

Flexible mining hose gives you greater design tolerance and is easy to install

No more shutdown headaches. Flexible hose gives you some wriggle room during installation—you’ll avoid expensive install dramas when things don’t fit.

Need even more flexibility? Try our Slurryflex SF-Series. It’s the most flexible mining hose in the world.

We’ll help you find smarter reliability fixes based on years of real world experience.

Proven on the world’s toughest mine sites

Explore the full Slurryflex range

You’ll enjoy more uptime & less maintenance with our premium, Australian made mining hose.

Related articles

Read more

Talk to a Slurryflex hose specialist

Tired of bandaging spools in your plant? Our specialists will help you unlock easy maintenance wins with Slurryflex.