The senior maintenance supervisor and his team were frustrated at how much this pulled them away from other, more pressing maintenance.

We had a look and identified two major problems:

- Tight bends: Fast, free-falling slurry was hitting the bottom of the bend and holing out the outer ridge of the spool. That was causing the blowouts.

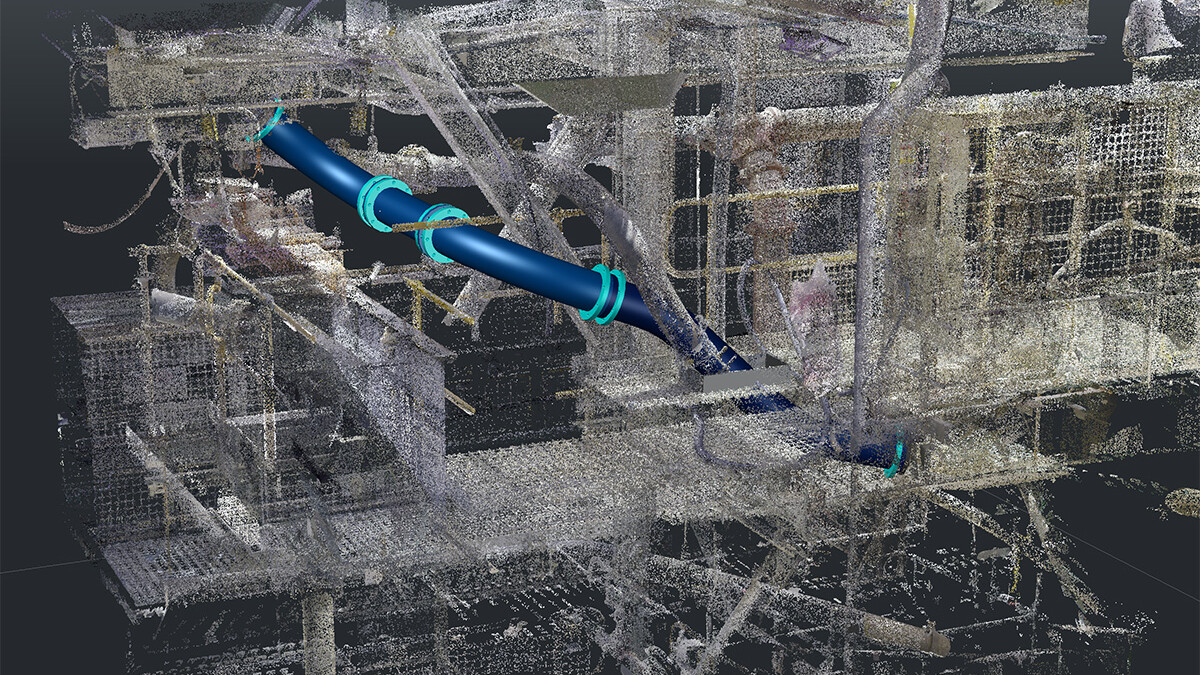

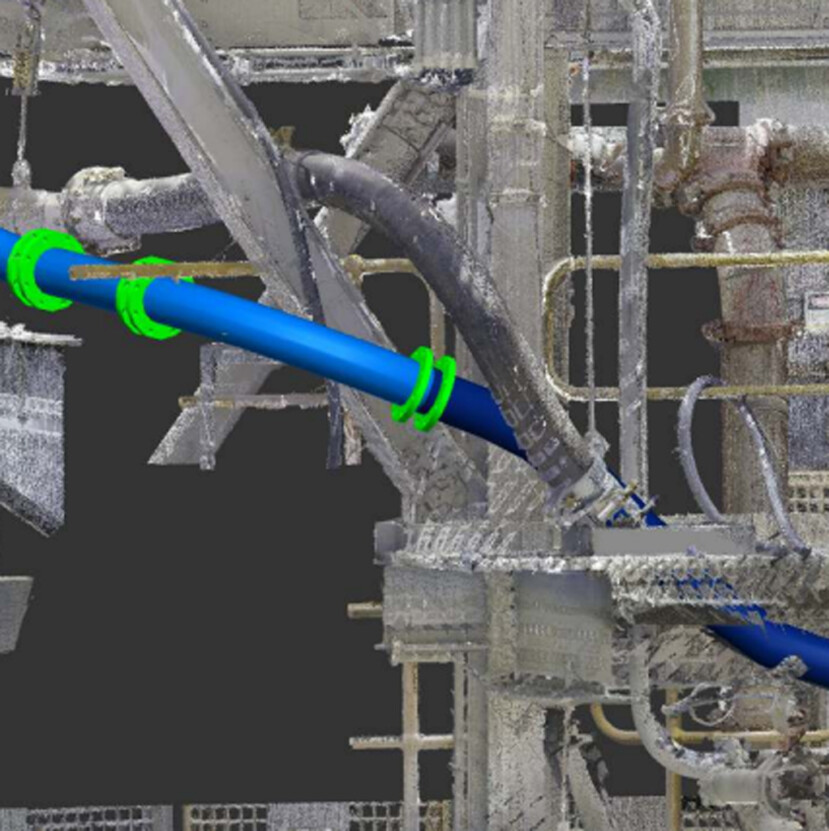

- Pipe elevation: The line snaked through structural cross brace, so there was a slight elevation where the pipe went over the brace (see scan image here). That was leading to blockages. The team cleared this through a flushing port, but it was an almost daily battle to keep the slurry moving.

We recommended that they refine the layout of the piping geometry. It would do two things:

- ‘Slow down’ the slurry: A longer, smoother bend radius reduces the speed and wear on the bends.

- Remove piping elevation: Moving the pipe below the cross brace removed the elevation. It would slow down blockages forming and drastically reduce the need to flush the line.

The supervisor decided to go ahead with the new design in Slurryflex CLX ceramic lined hose to beef up the wear resistance further.

It’s a small change that’s paid off two-fold. He’s improved the wear life of the new line by at least 4x.

Plus, he found that he could ‘speed up’ the line by enlarging the bore to push more through the line. It has further improved productivity at the plant.

Durability Improved wear life 4x

Slower slurry No more tight bends

Long wear life Set & forget piping