Newmont Gold Mine – Longer Lifespan Hoses for Dewatering Program

The dewatering hoses at Newmont’s Boddington gold and copper mine were only lasting 3-6 months before splitting and tearing on the pit floor’s rough surface. It was causing delays – and added costs – to their dewatering program.

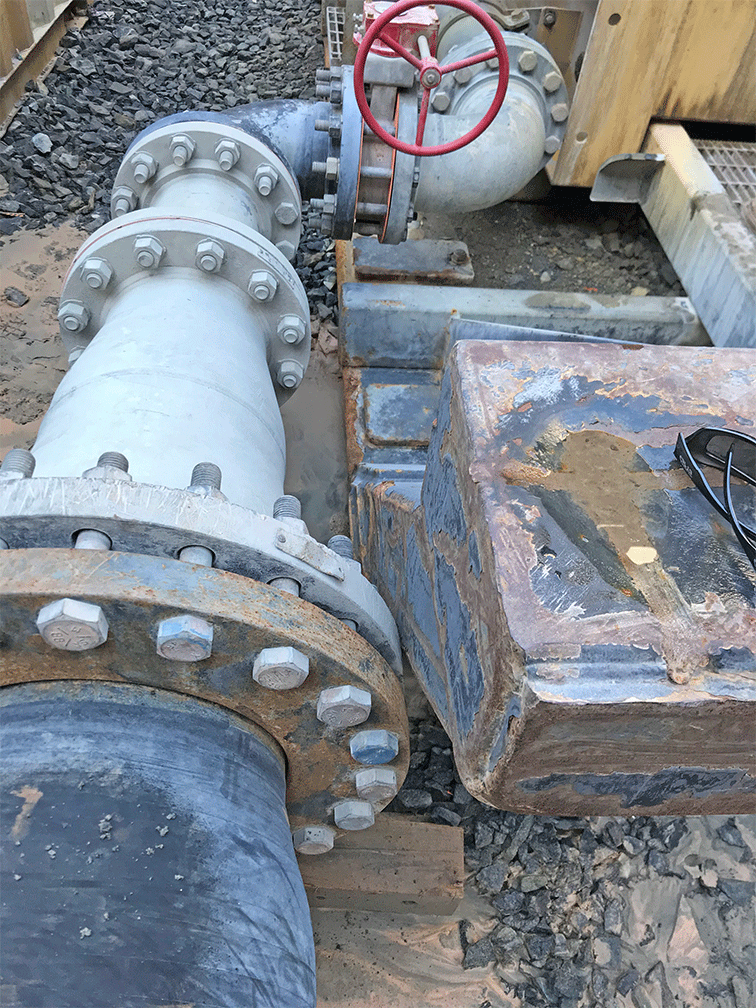

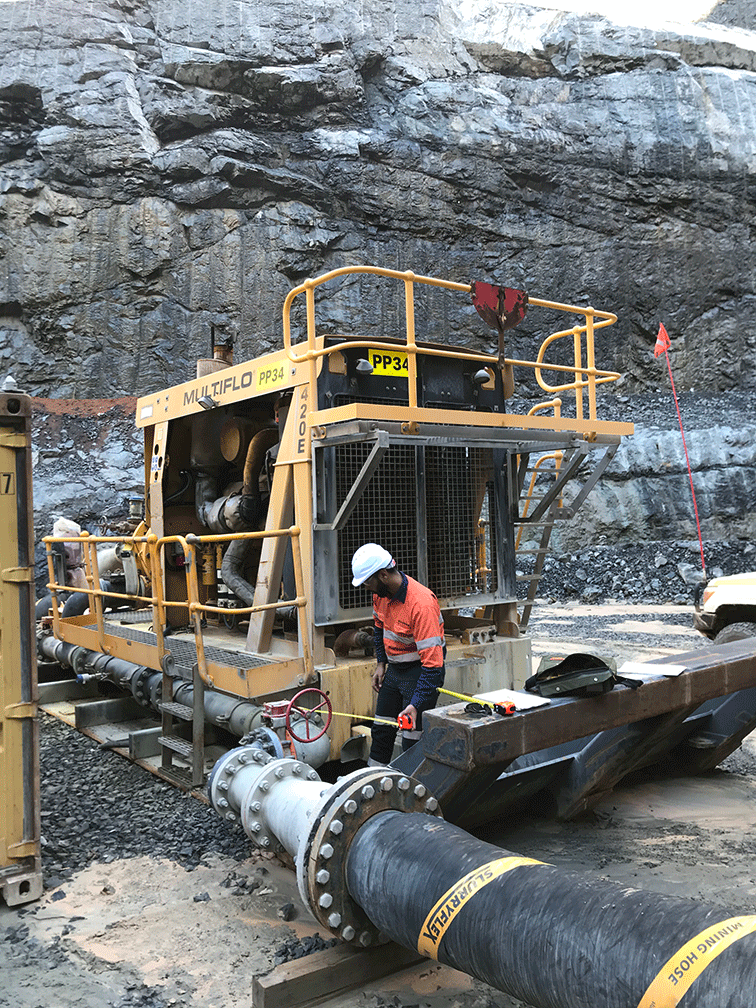

To combat the splitting hoses, we recommended they look at some harder-wearing options that would be more resistant to abrasion, punctures, and tearing. They decided to choose Slurryflex SA mining hose instead of an industrial hose. It’s rated up to 50bar with a tough outer layer, and the hot vulcanised end connections provide extra resistance to tearing at the flanges.

We also suggested simplifying the pump set-up to provide more clearance around the skids for easier maintenance. This helps stop leaking from the end connections and reduces inventory.

The Slurryflex slurry hose is now lasting 3-4 years before it needs replacing. This allows the team to spend time on other projects rather than fixing punctured hoses. They can get on with pumping the water out and making the pit operational again.

Client

Newmont Client Logo

Year 2020

Project size $0.1M

Location WA

Related content

Didipio Gold Mine – Floating Hose Solution for Dewatering Program

Cloudbreak Iron Ore Mine – Valve Spec Review for Dewatering Program

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.