Mt Whaleback Mine – Valve Redesign for Ammonium Nitrate Hoppers

We were pleased to help the Mt Whaleback team with the isolation valves on their ammonium nitrate hoppers.

They weren’t getting reliable control with their existing set-up and asked for our advice. So, one of our Perth-based valve engineers jumped on a plane up to Newman to review the valves and make some recommendations.

Client

Year 2022

Application Ammonium nitrate hoppers

Engineering Fail-safe valve redesign

Location WA

On the site visit, he could see that the linkage set-up of the positioners was unreliable, and this was causing the valve to frequently malfunction.

We suggested they redesign the interface between the valve and positioner, and include a fail-safe shut off to make it more reliable.

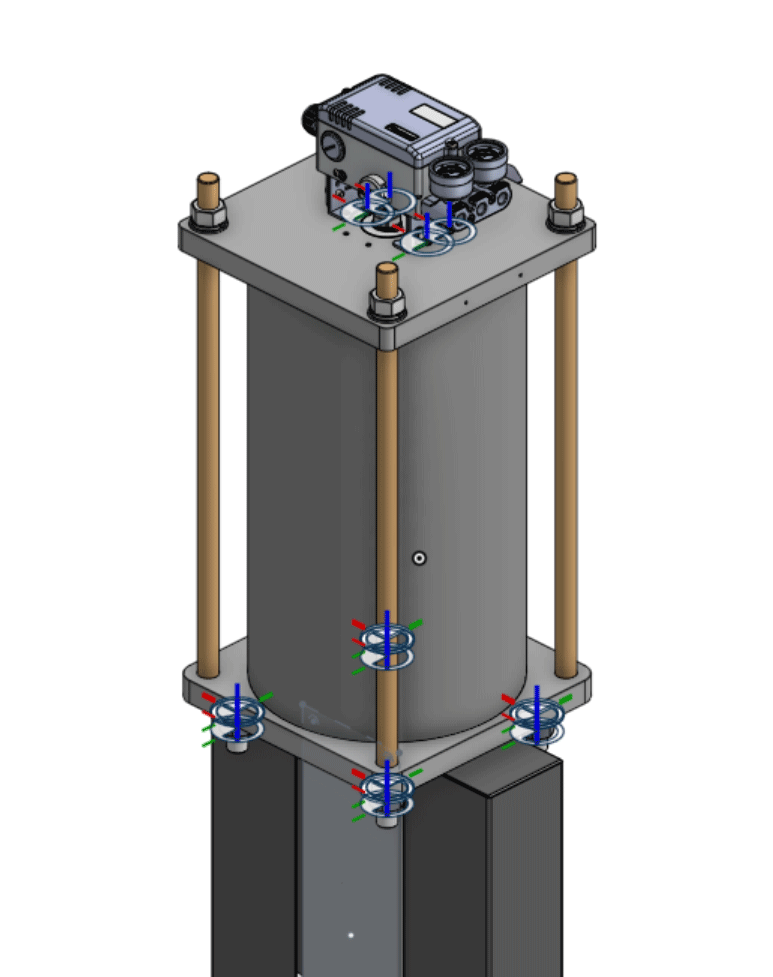

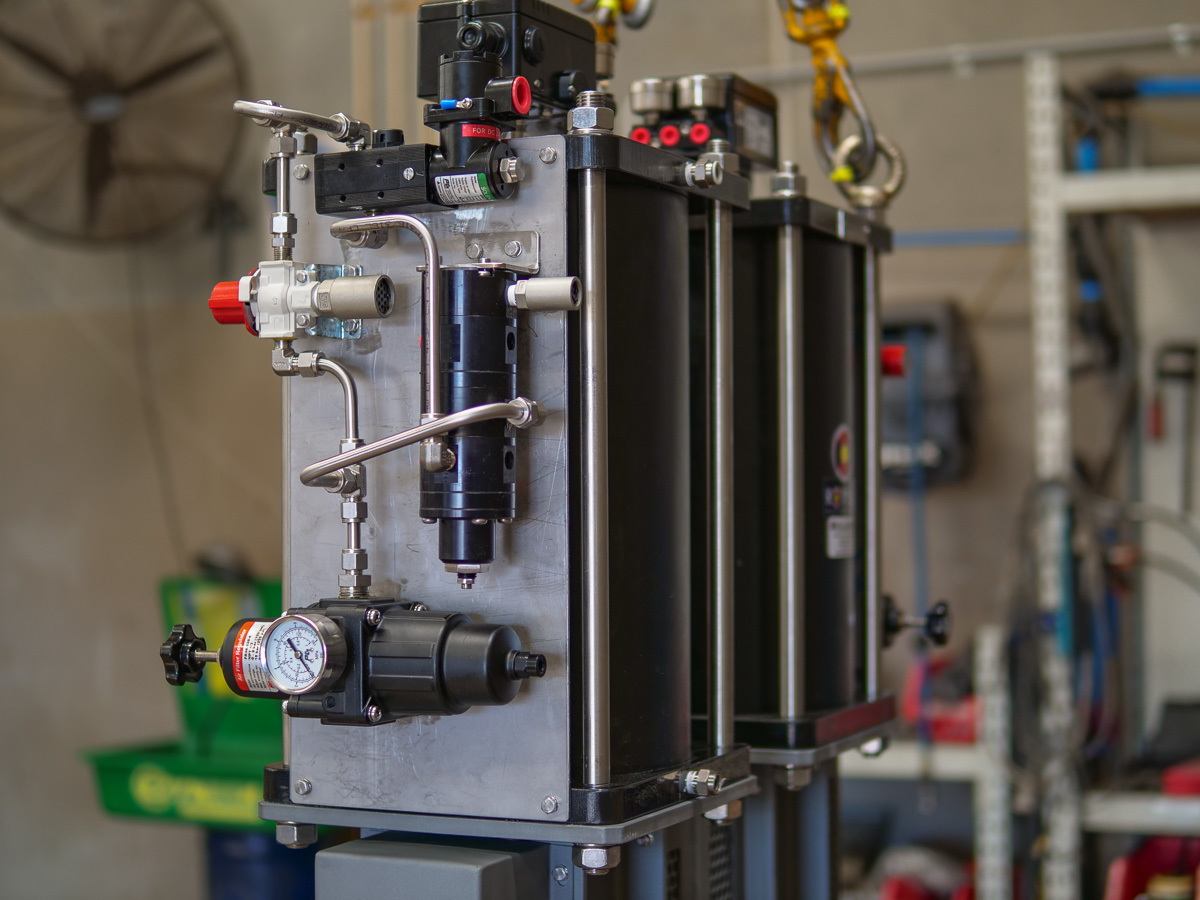

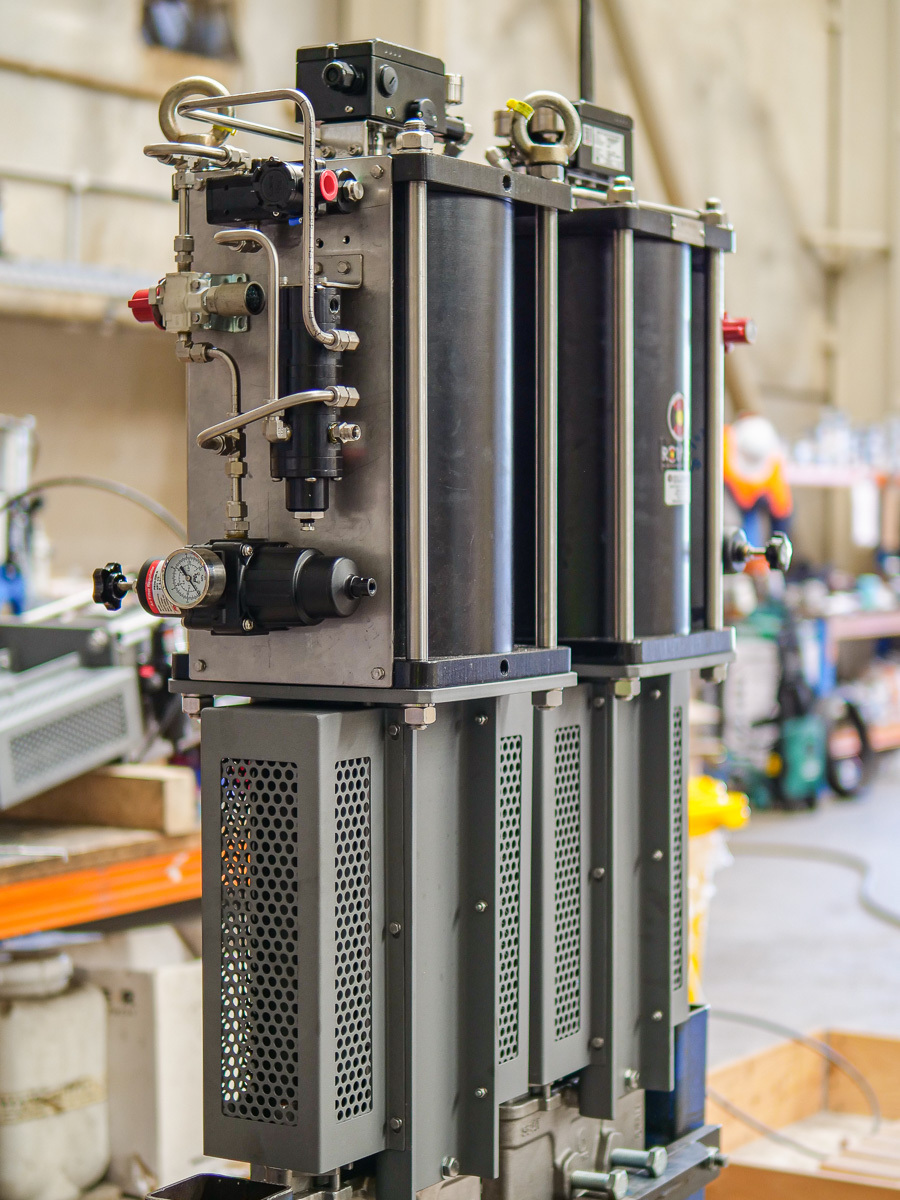

The BHP team agreed with our approach and asked our engineers to come up with a design. We designed a fail-safe system that ensures that the hopper isolates on manual emergency shutdown, loss of power, or a drop in pneumatic pressure.

Then we assembled the valves, fitted with actuators and controls, and fully tested them in our Perth valve workshop. Once they arrived on site, they were ready to install in a plug-and-play state.

It’s a great outcome for Mt Whaleback and we’re pleased we could offer our expertise to help make their site more reliable.

Related projects

How Roy Hill Solved Costly Unplanned Piping Maintenance for Good

WA Lithium Mine get 12x Longer Wear Life in Slurry Control Valves

8x Longer Lifespan for Cyclone Overflow Piping at FMG Solomon Mine

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.