When rubber lined steel piping isn’t lasting the distance, we often see maintenance teams try ceramic lined steel pipe as an alternative.

Their thought process makes sense. Ceramic tiles give better sliding abrasion compared to rubber, so you should get longer wear life.

But, in practice, it doesn’t usually give them the performance increase they were looking for. In this article we’ll look at why that happens and show practical examples of how mining engineers have solved the problem.

Causes of ceramic tile failure

We have seen plenty of failed ceramic lined steel spools in our customer’s plants. They tell us that the most common problem is dislodged and debonded tiles.

The remaining tiles typically have plenty of wear life left, they just don’t always remain bonded to the pipe. Once they start dislodging in one spot, it’s only a matter of time before the whole spool fails.

They tell us that when the first tile lifts and peels away, the slurry erodes the remaining grout and works its way under the neighbouring tiles. This can then peel away whole sections of tiles, which exposes the bare steel, causing pipe failure.

Once a tile falls out, it leaves a hard edge. These ridges create turbulence, which can cause more problems downstream. Our customers also report that dislodged tiles can then get stuck in equipment like cyclones and pumps.

We received this photo from a site recently that clearly shows all of these issues. You can see that slurry has ripped entire sections of tiles away leaving the rest of the grout and steel pipe exposed.

Why does ceramic lined steel pipe fail like this?

In our experience, there are two main reasons why ceramic-lined steel fails like this:

- How it is manufactured

- Rigid steel pipe combined with rigid steel tiles can’t absorb impact and vibration

The manufacturing process & consistency

Manufacturing ceramic-line steel spools is a labour intensive, manual process. As a result, our customers tell us that they find the quality of gluing and grouting varies significantly. The tiles in ceramic lined steel are glued in as individual tiles or strips. This can create ridges in the lining that chip or peel the tile and give the slurry openings to work its way under the tiles.

You can see that in this photo. One tile has already dislodged, and the grout around it is being eaten away. It is only a matter of time before more tiles go.

Slurry impact and absorption

Ceramic tiles have excellent wear resistance but they’re poor at absorbing impact. Rigid steel pipe also has no give. So, when slurry hits the pipe walls, (such as when there’s a change in fluid direction, tight bends, or turbulence) over time you get hot spots that bear the brunt. Vibration around pumps can also cause problems with the rigid combination of ceramic tiles and steel piping.

How other sites have solved the problem

Our customers find they get better results when they use ceramic lined rubber mining hose in highly abrasive, turbulent areas in the processing plant.

They get the biggest wear life improvements by using Slurryflex CLX ceramic lined mining hose in areas such as:

- Mill discharge lines

- Pipework connecting to slurry pumps

- Cyclone feeds

- Cyclone overflows and underflows

- Gravity circuits

- High impact bends (where high velocity slurry is rapidly changing direction)

The reason Slurryflex CLX is so effective is that it addresses all of the shortcomings of ceramic lined steel pipe.

We use small hexagonal fine grain alumina ceramic tiles and embed them into the rubber liner of the mining hose. Hot vulcanisation then securely bonds the ceramic tiles into the hose with a seamless surface.

We’ve perfected this over years with a proprietary manufacturing process. With 1000s of these hoses in use in severe slurry conditions around the world, we’ve never seen a tile debond.

Using a rubber hose rather than steel pipe addresses ceramic’s other weakness – impact absorption.

Sites that have trialled different lined piping options in their process always find that our ceramic lined mining hose absorbs and dissipates impact from particles better than rigid pipe.

Where slurry changes direction or is turbulent the mining hose carcass gives extra rebound so slurry particles will rebound off the tile, reducing wear and extending the life of your piping.

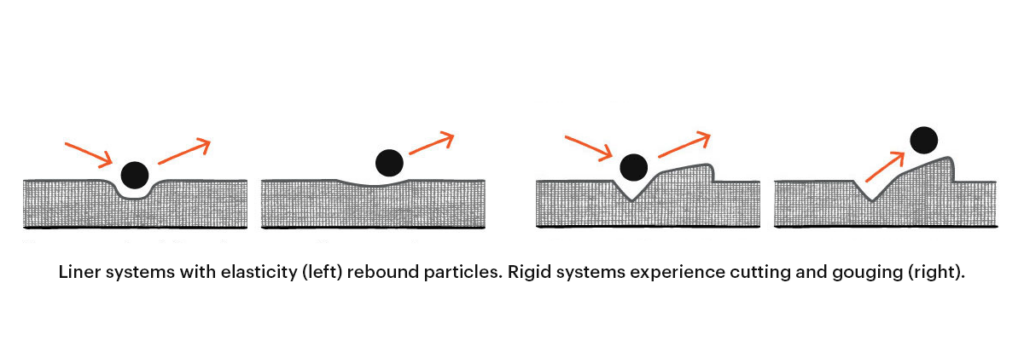

You can see that in the diagram below that shows plastic and elastic deformation wear mechanisms. When both the wear liner and the substrate are rigid (which is the case with ceramic lined steel), you end up with much higher wear. The chipped and worn tiles are more vulnerable to dislodgement, leaving you with fast wearing pipework.

When both the wear liner and the substrate are rigid (which is the case with ceramic lined steel), you end up with much higher wear. The chipped and worn tiles are more vulnerable to dislodgement, leaving you with fast wearing pipework.

Rubber mining hose is also easier to handle than steel pipes and the flexibility make it easier to install.

Results from other mine sites

We’ve helped numerous maintenance teams reduce downtime and increased wear life by moving to Slurryflex CLX. Here are some examples of their results.

Kansanshi Copper-Gold mine: 5x wear life on fast wearing slurry lines

The ceramic lined steel on their high wear slurry lines was failing within nine months. The downtime and lost production to replace the DN600 pipe was frustrating and costly. They decided to trial Slurryflex CLX against ceramic lined steel. Their result? Five times improved wear life.

FMG Solomon iron ore mine: 8x longer lifespan on cyclone overflow piping

Despite moving from rubber-lined steel to ceramic lined steel, the maintenance team at FMG Solomon were still replacing their cyclone overflow piping every 10 to 12 months. Ceramic lined mining hose has given them an 8x longer wear life on their piping.

Argyle Diamond Mine: 12x improvement on de-grit line piping

At the Argyle Diamond mine, the maintenance team had spent more than 1000-man hours to fix leaking and fast wearing ceramic-lined steel on their de-grit line. Replacing it with Slurryflex CLX fixed the problem for good with a 10x increase in wear life.

Newcrest’s Cadia Mine: 2+ year lifespan on slurry pump spool

The reliability team at Cadia mine have eliminated a long-term maintenance problem by replacing their slurry pump spools with Slurryflex CLX. It has already outperformed the ceramic-lined steel spools.

Mt Pleasant mine: 6x wear life with pump reducer

Slurry pump piping was playing havoc with the operations at the Mt Pleasant mine. The ceramic-lined steel spools on tailings pumps were only lasting three months. They are now getting 6x more ceramic-lined mining hose.

Want to fix problem problem piping in your plant?

The reliability teams we work with find that Slurryflex CLX gives them better plant performance with more uptime and throughput.

They worked out that while ceramic-liners will give extra wear resistance, using ceramic-lined steel does have drawbacks.

Ceramic lined mining hose gives you the best of both worlds – wear resistance with flexibility that can withstand turbulent and highly abrasive slurry applications.