Designing a pipeline is a serious challenge. When you get it right, installation happens on time, commissioning is a breeze, and the pipeline lasts for the planned design life.

Getting it wrong isn’t really an option.

You have lots of factors to consider. One area we see that’s often overlooked in pipeline design is pipe spool length.

Specifying 18m spools—rather than the standard 12m lengths—makes a big difference to your pipeline’s efficiency, safety, and cost.

In this article, we look at how this small change helps at every stage of the project, from a more efficient design and installation, right through to maintenance.

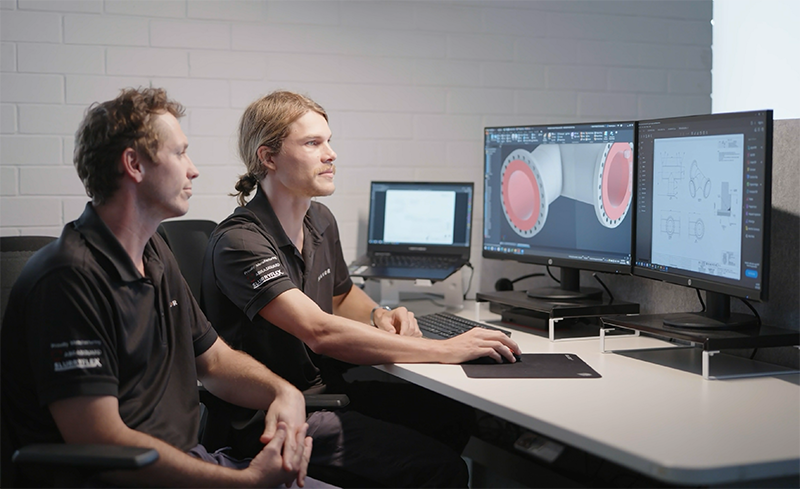

Simpler, lower cost design

Longer length spools mean fewer joints across the length of the pipeline, so there’s less risk of leaks caused from poor assembly or connection design.

Traditional liner systems can only be manufactured to a maximum of 12m lengths. This limitation has a flow-on effect to the rest of the pipeline design. With shorter spools, you need to factor in more spools across the length of the pipeline, and increase the number of bolts, gaskets, or welds. All this adds to cost of the project.

Some polyurethane polymer liners, like Abrasiguard, are now built in 18m lengths, and this is making new pipelines more efficient.

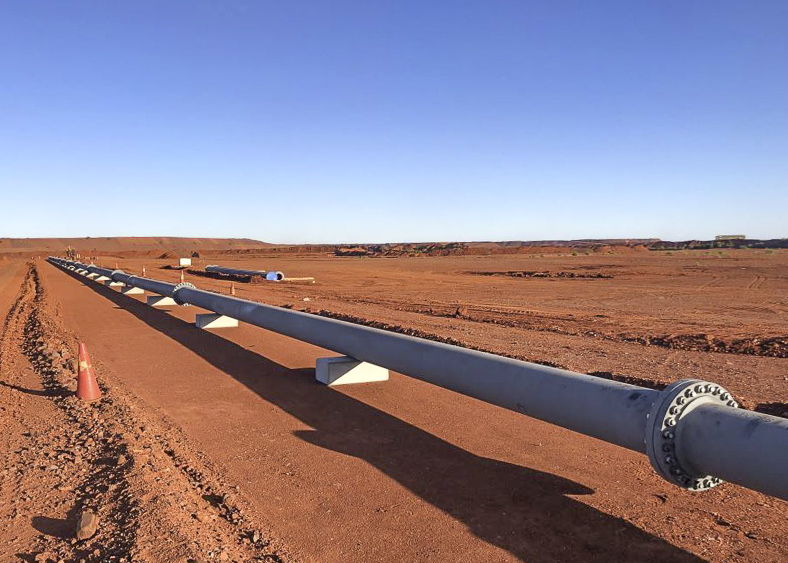

This was a factor for the designer engineers working on Rio Tinto’s Robe Valley Sustaining (RVS) project in WA’s Pilbara. They chose 18m spools for the new 13km iron ore slurry pipeline. Overall, the project used 30% less spools by specifying longer lengths.

Install faster

When you use 18m spools, you need fewer trucks to string out the pipeline, fewer cranes for lifting and placement, and less labour for welds and bolting.

The RVS brief originally called for standard 12m lengths. But, after working through the specifications with the design engineer, they realised that 18m polymer lined pipes would be more efficient.

They initially allowed for 1083 x 12m spools but ended up with only 722 x 18m spools.

Below we’ve compared the average installation costs of two, 13km DN300 pipelines—one built with 12m spools, and the other with 18m spools.

You can see that 18m Abrasiguard spools are 17% cheaper as a supply price, but substantially more cost effective as a supply and install price.

Table 1: Supply price of 12m rubber lined vs 18m Abrasiguard polymer

| 12m | Cost | 18m | Cost | % saving | |

|---|---|---|---|---|---|

| Pricing index | 1083 lengths | 1.0 | 722 lengths | 1.25 | 17% |

Table 2: Installation costs of 12m spools vs 18m spools

| 12m | Cost | 18m | Cost | % Saving | |

|---|---|---|---|---|---|

| Trucks $6000/truck | 6 pipes/truck (181 trucks ex. Perth) | $1,086,000 | 6 pipes/truck (120 trucks ex. Perth) | $720,000 | |

| Cranes (8 joints/day) | 1083/8 x $4000 crane | $541,500 | 722/8 x $4000 crane | $361,000 | |

| Labour | 3 techs @ $175/hr x 1083 joints | $568,575 | 3 techs @ $175/hr x 722 joints | $379,050 | |

| Gaskets | $300/gasket (if required) | $324,900 | $300/gasket (if required) | $216,600 | |

| Bolts | 16/joint x $15/bolt x 1083 | $259,920 | 16/joint x $15/bolt x 722 | $173,280 | |

| Install costs | $2,780,595 | $1,849,930 | 33% |

*All prices in this table are indicative and provided for information purposes only.

Your install labour costs increase with shorter lengths. You need to lift the pipes into position, align them and torque up of bolts, which is a very timely process.

With only one third of the joins, your installation crew is substantially quicker and you save on labour costs.

Roy Hill’s Zulu 6 pipeline uses 18m lengths

Maintenance is cheaper and easier

The spool size also affects maintenance long after commissioning.

You also spend less time monitoring the pipeline over its lifetime with 18m spools. Over a 13km pipeline with 12m pipes, there’s more than 1,000 joints to inspect regularly. With 18m pipes, there are 722 to check.

Less joints means fewer items to catalogue in your inventory systems and to have on site for repairs.

Set, forget and move on

A well-designed pipeline should last the life of your mine, and even longer.

For your next pipeline project, look at 18m lined pipe lengths. You can reduce labour and install costs as well as monitoring and inspection outlays.

This small change could make a big difference to the cost—and success—of your pipeline.

Get practical recommendations for your pipeline

Reach out to setup a call with a pipeline specialist. We'll give you clear recommendations and advice to help you with your piping specification, so you can confidently design a pipeline that lasts.

"*" indicates required fields