If you spend enough time on mine sites looking at slurry piping, you get to see what works and what doesn’t. When it comes to choosing between muff coupling or integral flanged hose, it’s pretty straightforward.

In our experience, muff coupling hose should only be used in two specific circumstances:

- When you need to cut hoses to length on site.

- When you need a temporary quick fix in between shutdowns.

We’ve put together this summary of the pros and cons of the two types of hose connections and what will work best for your plant.

What are muff coupling and integral flanged hoses?

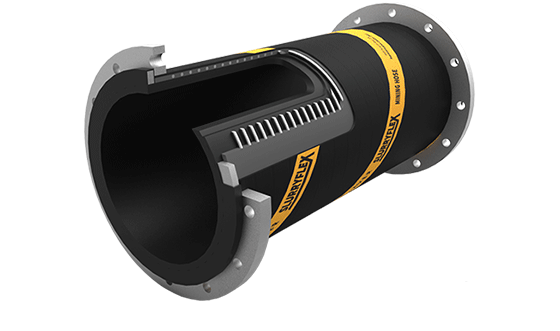

Integral flanged hose is custom made to fit with connecting pipework in your plant. The flange—such as fixed, swivel or full spigot—is built directly into ends of the hose during the manufacturing process.

Integral flanged hose

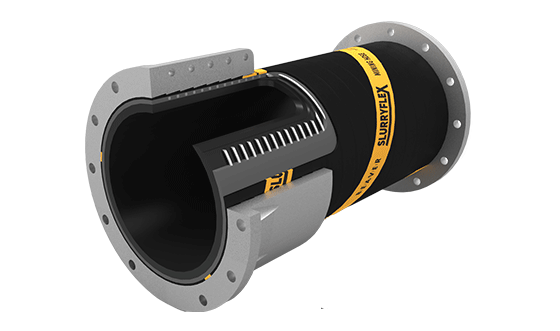

Muff coupling hose is an off-the-shelf product that can be cut to length on site and attached to existing pipework with a cast iron or aluminium split shell muff coupling. It is bolted to the flanged ends of the connecting hose and tightened into place.

Muff coupling hose

Advantages of muff coupling hose

Muff coupling hose is a good option when you need to quickly fix a split or leaking hose. The hose can be bought ready-made and held in stock onsite for maintenance.

Plus, muff couplings are a separate fitting so they can be reused many times when replacing worn or damaged hose.

Muff coupling hose is also handy during the construction of a new processing plant. Because it can be cut to length on site, it gives you some flexibility when you’re still working out the exact lengths needed for a particular line. After commissioning, you can phase it out with longer lasting integral flange hoses.

✔ Can cut to size onsite

✔ Excellent band-aid fix for split or leaking hoses

✔ Great option during construction when working out lengths

✔ Couplings are re-usable

Disadvantages of muff coupling hose

Muff coupling hose is a good option for fast and convenient repairs, but beyond that it’s limited in what it should be used for.

As an off-the-shelf product, muff coupling hose only comes in standard sizes (between DN50 to DN400). The hose has a standard 6mm wear liner thickness, as the hose’s outer diameter must match the muff coupling inner diameter, so it’s not suitable for high wear applications.

It has a working pressure limit of 7-10bar, so is restricted to low-pressure applications. It is also restricted to a bend radius of 10D or larger.

Cutting the hose to length on site—while handy—also has its pitfalls if not done correctly. If the hose is cut too short, it’s unusable, cut too long, and you’ll end up with kinks and bends. This is a common problem and one we often see in mineral process plants.

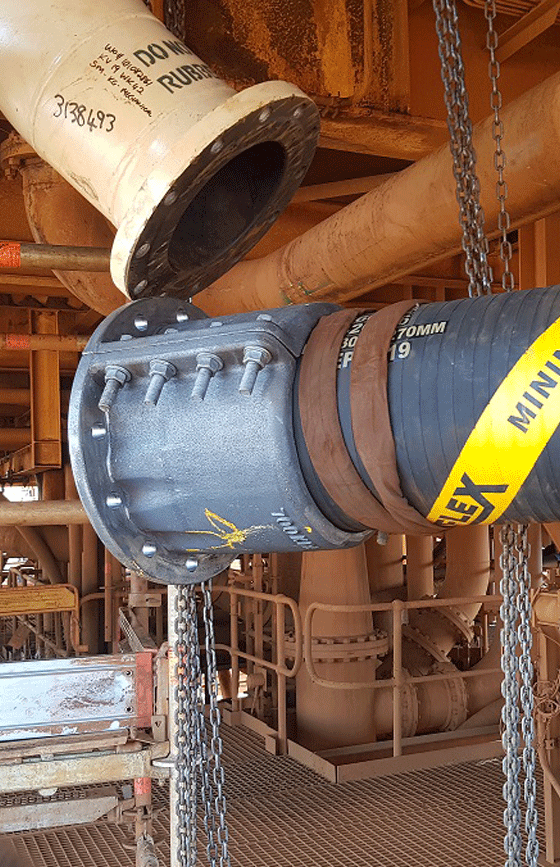

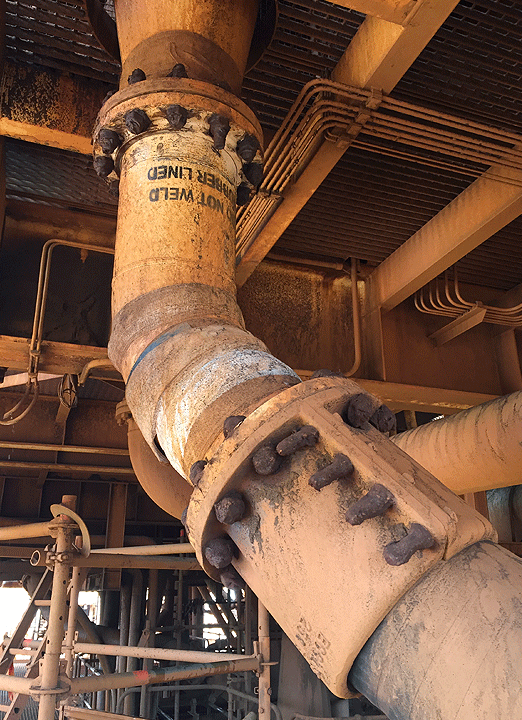

As you can see from this photo, the hose is installed without being cut to the right length, causing blockages in the pipework and increased wear on the hose. That means more maintenance and unplanned shutdowns to fix the problem.

Finally, muff coupling hose is not suitable for applications where there is ‘end pull’—where hoses are hanging from the muff coupling connection. It’s a serious safety hazard and we’ve seen near misses from falling pipework caused by muff coupling hose pulling off flanges.

✖ Pressure, size and flexibility restrictions

✖ Incorrect cutting and fitting causes kinks and blockages

✖ Serious safety hazard if used incorrectly

✖ Shorter lifespan means more maintenance

Advantages of integral flanged hose

You can customise almost every component of an integral flanged hose. The hose is manufactured in a wide variety of sizes, end connections, and specifications.

It is also a good option where you need a very tight bend radius (smaller than 5D). Because it’s custom made, the hose can be made with a pre-formed bend as part of the manufacturing process.

Integral flanged hose is the best option for high-pressure or high-wear applications. It can be customised to any pressure rating (up to 50bar as standard but as high as 200bar on request) and for most slurry or fluid types. You also have the option of increasing the liner thickness or different liner types for more abrasive or corrosive applications.

It’s for all these reasons that integral flanged hose adds up to being a better performing hose, with a longer lifespan, compared to muff coupling hose.

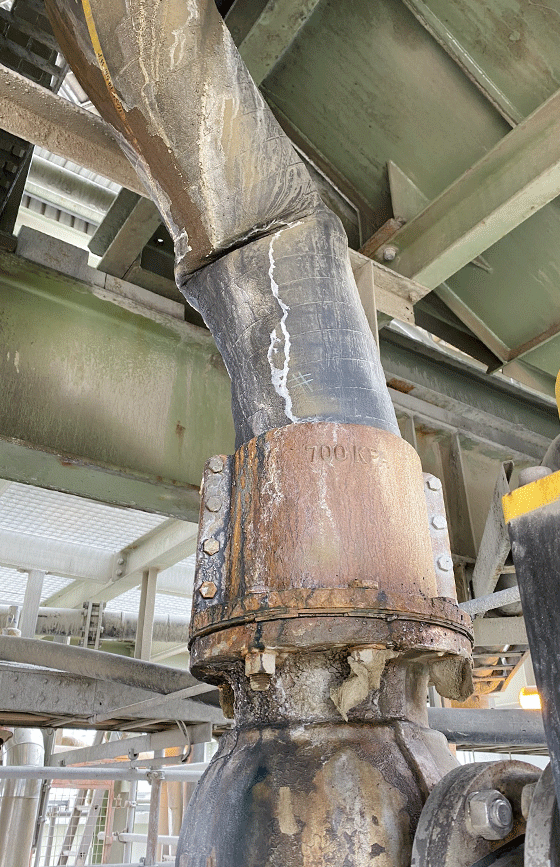

As you can see from this photo, our customer decided to swap out the muff coupling hose to integral flanged hoses. They’ve found the new hoses are lasting longer, so this means less maintenance and no leaking or blockages.

✔ Fully customisable

✔ Ideal for high-pressure applications (up to 50bar as standard)

✔ Suitable for a wide range of abrasive and/or corrosive fluids

✔ Longer lifespan compared to muff coupling

Disadvantages of integral flanged hose

The customisation of integral flanged hose is a key advantage, but there are some downsides to this type of hose. The first one is cost. Integral flanged hose is more expensive because it’s custom made. However, when you weigh up the longer lifespan versus the increased replacement and maintenance costs of muff coupling hose, you can see the benefits.

Secondly, the length of the hose is fixed, and it can’t be cut on site. You need to make sure your measurements are right when ordering the hose.

Finally, lead times are longer. As each hose is custom made, delivery can take 4-8 weeks. That’s fine for planned maintenance, but tricky if you’re dealing with unplanned breakdowns.

✖ Higher initial costs

✖ Length of hose is fixed so measuring is key

✖ Longer lead times

Which is the best choice for you?

In our experience, integral flanged mining hoses are a more reliable option. They’re custom made to suit your application, have a longer lifespan, and provide more durability over muff coupling hose.

Sometimes, you might be looking for a fast fix to keep your plant running. If that’s the case, muff coupling hose will work well temporarily for most standard applications. But make sure you consider the limitations carefully before committing to using it in your plant.