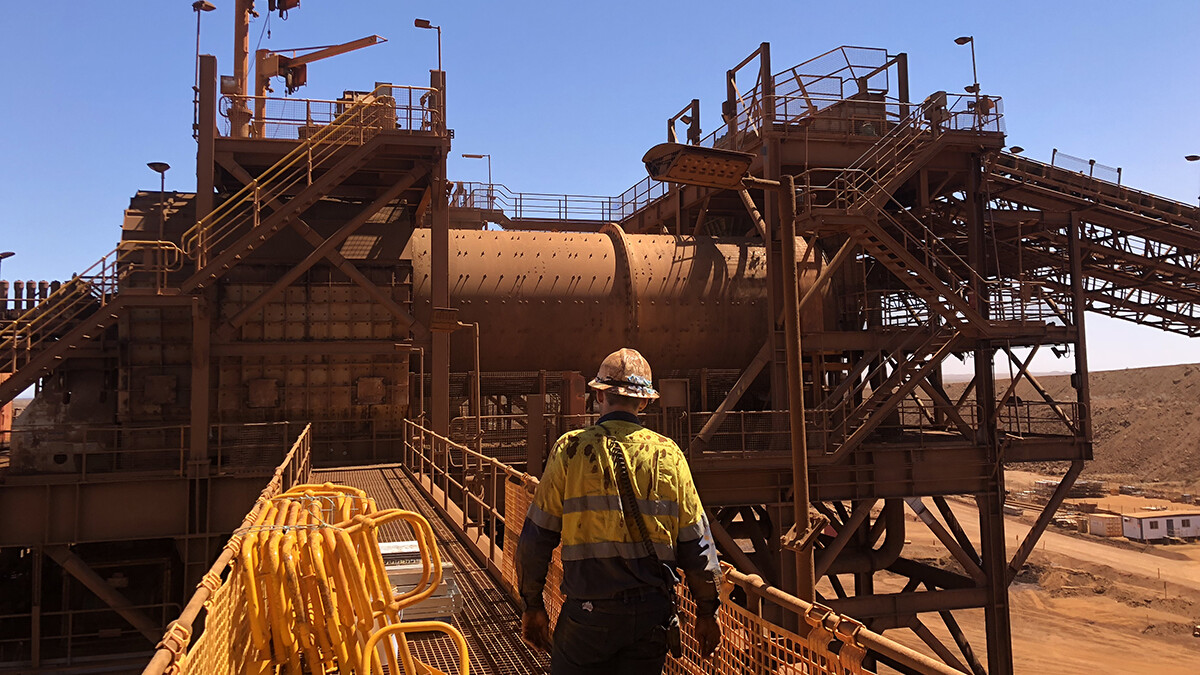

As global iron ore demand wanes, optimizing plant performance is more critical than ever.

Unplanned shuts to replace piping will eat into your site’s profitability. That’s why smart maintenance teams are getting on top of common piping problems in their iron ore plants.

They find ways to make their piping work for them, rather than against them. Here’s how they do it:

Spiral launder piping: FMG Cloudbreak

At FMG’s Cloudbreak mine, the piping under the spiral launders was a mess. The piping – a mix of HDPE and rubber lined steel – was wearing out at different intervals, often within weeks.

High wear in spiral launder piping is really common. Turbulent slurry particles exit the launders and gouge into HDPE and rubber lining, causing leaks and early spool failure.

The engineer at Cloudbreak redesigned the piping to move away from HDPE and rubber-lined steel towards something that would give better wear resistance.

To increase wear life on the bends, he introduced more flexibility. He found the best way to do that was to introduce ceramic-lined mining hose. Hose absorbs and dissipates impact from the change in slurry direction, while ceramic tiles give extra wear resistance. On the straight spools he swapped to Abrasiguard polyurethane-lined steel as it has excellent resistance to abrasion and sliding wear.

The results? The new piping has lasted 10x longer than the rubber-lined piping and 20x longer than the HDPE spools. They have increased throughput and made significant savings in their maintenance budget.

Cyclone feeds & distributors: Rio Tinto Tom Price

Rio Tinto’s Tom Price maintenance team made a few design changes and doubled the lifespan of the cyclone feed clusters.

They were frustrated by endless bandaging on kinking and splitting feed hoses.

So they shortened and standardised the hoses across all the clusters.

This does two things. Shorter lengths are less likely to kink and split. If you standardise hose lengths, you can quickly swap one out for a spare. That reduces cataloguing and downtime while you wait for a replacement to arrive.

We also added wear monitors to their DN150 Slurryflex hoses. This took the guesswork out of knowing when hoses needed replacement.

These small tweaks have put an end to leaks, splits and downtime in this key area of their plant.

Slurry pump piping: Roy Hill

This simple design change has doubled the lifespan of slurry pump piping at Roy Hill.

The existing slurry pump piping setup was a common one. They were using two rubber-lined steel spools—a straight spool and a reducer—and a flexible coupling to connect the pump and adjoining pipework.

But the maintenance team found that the rigidity of steel spools amplified pump vibration. This caused misalignment and leaks. Slurry would build up underneath and make the plant floor slippery – a real hazard for the maintenance team. Plus, it’s a difficult job to remove the steel spools for inspections and maintenance to pumps.

They decided to streamline things by changing to a single ceramic-lined mining hose reducer. It’s one piece instead of three.

Their pump piping now lasts twice as long and they save hours of work when it’s time for pump maintenance and inspection.

Upcurrent classifiers: FMG Solomon

FMG Solomon’s fixed plant maintenance engineer was completely over replacing pipework in the plant’s up current classifiers (UCC).

The rubber-lined steel spools were failing within six months and this was pulling their team away from other critical maintenance jobs.

Iron ore concentrate is extremely abrasive and hard so you need pipework that has high abrasive wear resistance.

The maintenance engineer was keen to trial polyurethane-lined steel after seeing it in action at other FMG sites. It outperforms older lined piping technology – such as rubber-lined steel – in wear resistance and lifespan. That reduces maintenance costs and downtime.

The new UCC piping set up paid off for the team. It’s lasted more than 4x longer than the rubber-lined steel – delivering an annual maintenance saving of more than $300,000.

Cyclone underflow: Rio Tinto Marandoo

The maintenance team at Rio Tinto’s Marandoo site were constantly let down by their underflow piping.

The HDPE spools were holing out within months. This caused costly unplanned shuts to bandage or replace piping.

The biggest issue with rigid elbows? They have no flexibility or shock absorption. So when iron ore slurry is free-falling in a gravity feed you end up with localised wear in one spot, usually on the outer arch of the elbow.

That’s why the team switched to flexible mining hose. It can absorb and dissipate the slurry impact along the entire length of the hose. This extra flexibility also makes life easier when installing or replacing the spool.

The team have extended the life of the piping by 300%, keeping their plant running better for longer.

Learn from what works

These teams have discovered smarter piping maintenance strategies that work for their sites. If you’re replacing the same spools over and over again, look at what other sites are doing to find a better way.

When you take the time to find proactive upgrades, it does more than reduce your spool replacement and labour costs. You’ll free up valuable time and increase the throughput of your plant for a more efficient – and more profitable – operation.

Battling with failed slurry piping in your plant?

Speak with a piping specialist today. We’ll share real examples of sites like yours getting longer wear life and better reliability from their slurry piping and how you can achieve the same.

"*" indicates required fields