No two slurries are the same. That makes tailings transport a challenge, even for the most seasoned pipeline engineers. Fully understanding what you’re transporting could mean the difference between a straightforward pipeline project or one plagued with problems.

Dr Lachlan Graham is a research engineer in fluid dynamics at CSIRO. He says slurry rheology—the physics of the flow of matter—is often overlooked when designing pipelines.

“Slurry rheology range is a key influencer in pipeline design. At this stage in the process, you need to know the rheological properties of the slurry you’re working with,” he says.

“Otherwise, you could be in big trouble later on.”

Rheology testing is the most accurate way to understand how slurry behaves, but Lachlan says you can also apply basic principles to identify potential issues before they occur.

And that’s why we created this article. It gives you an introduction to the basic principles of rheology so you can make better design decisions on your next slurry pipeline.

Non-settling and settling slurries

A non-settling slurry is a uniform mixture of solids and liquids—the particles stay in suspension and don’t settle to the bottom. These particles are typically small (less than 60-100 microns).

Particles in a settling slurry are only in suspension when there’s agitation due to turbulence. Once pumping stops, the particles settle to the bottom of the pipe, forming a low-viscosity carrier fluid.

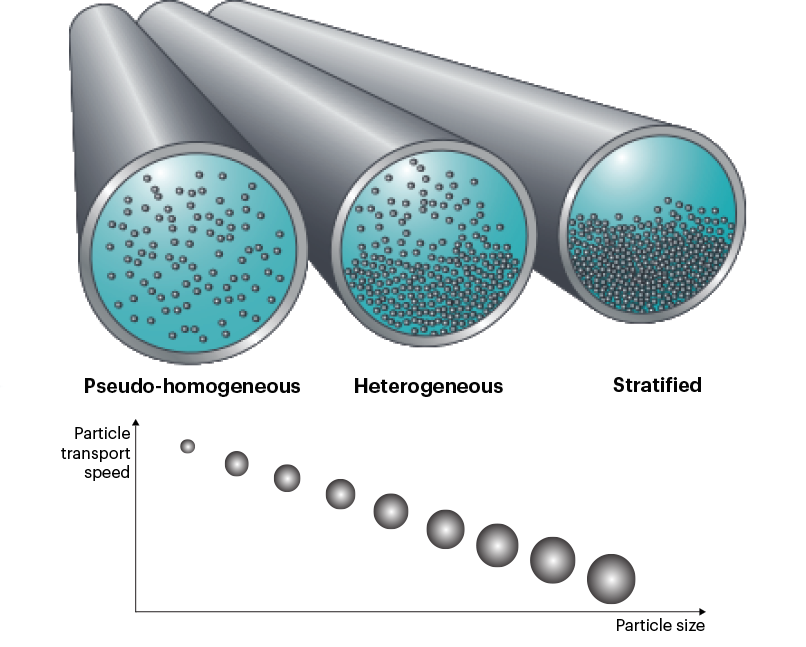

In the diagram below, you can see how different slurry types behave based on particle size and transport speed.

Source: Flygt Slurry Handbook

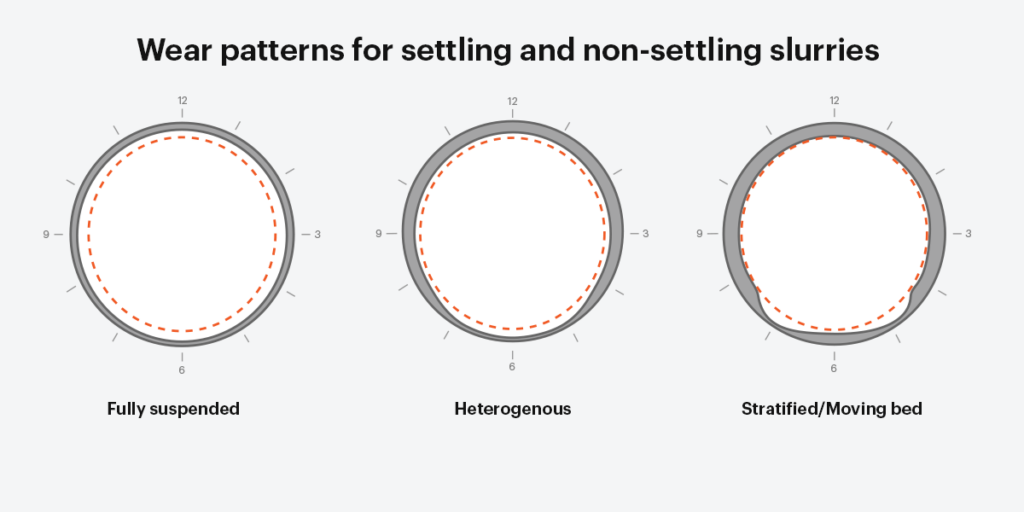

“If the particle concentration is the same at the top as at the bottom of the pipe, you tend to get reasonably even wear all around the pipe,” explains Lachlan.

“If you drop the velocity a little bit, you’ll start to see stratification. In that situation, you tend to get wear towards the bottom of the pipe.

With a static, non-moving bed, you’ll see very little wear on the base because nothing’s moving. But you’ll get a lot of wear outside of that bed.”

That determines the type of piping you’ll need. With a non-settling slurry, you may get away with using unlined steel or HDPE piping.

Settling slurries cause higher, uneven wear in pipelines. There are two reasons for this:

- Often pumping speed is increased to reduce settling. That increases turbulence in the pipe and erosive wear.

- The settled bed causes sliding bed abrasion on the bottom of the pipe. In this case, it’s best to use high wear lining like polyurethane.

Newtonian and Non-Newtonian slurries

Another way of classifying slurries is as Newtonian and non-Newtonian fluids.

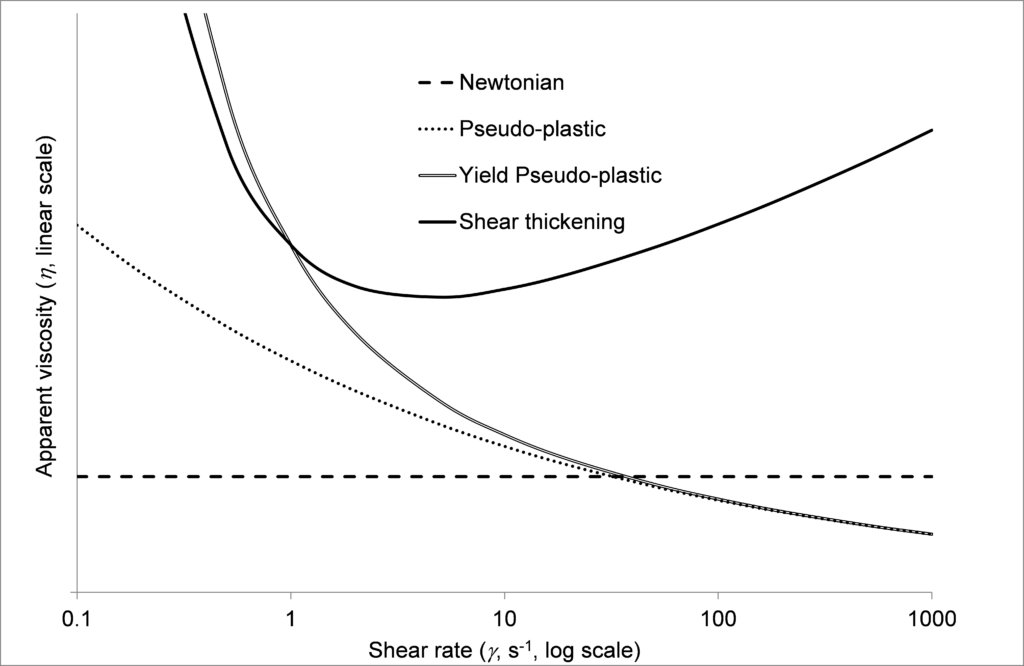

With Newtonian fluids, the viscosity remains the same, irrespective of the shear rate at a constant temperature. Some examples of Newtonian fluids are water, alcohol, or petrol.

Non-Newtonian fluids behave differently. With these, the viscosity of the slurry changes when shear stress is applied.

There are different types of non-Newtonian fluids. Tailings are often modelled as Bingham Plastic together with a coarse particle fraction. This is included in the pipe design models if there is a significant concentration of particles larger than 75 microns. These slurries won’t flow in a pipe until a minimum stress (such as pumping) is applied to overcome their yield stress.

The graph below shows how Newtonian and non-Newtonian fluids behave when shear stress is applied.

Newtonian and non-Newtonian fluids behave differently when shear stress is applied. Source: Clays in the Minerals Processing Value Chain

Whether a slurry behaves as a Newtonian or non-Newtonian fluid changes the pumping and transport regime. For example, higher viscous fluids like paste backfill may mean using a positive displacement pump rather than a centrifugal pump. With a more dilute slurry, you’ll be able to use a centrifugal pump but you’ll have to look at liner options to cope with turbulence of settling slurry particles.

That leads us to friction loss. Some liner technologies – like rubber-lined steel – have high friction loss. That’s a big deal for long-distance slurry pipelines because it can dramatically increase your pumping requirements.

Newer liners like polyurethane have very low friction loss, which reduces the head loss caused by frictional resistance on the pipe wall. That means you can run with lower pump power, potentially saving capital costs if you can use smaller or fewer pumps, and also reducing your energy operating costs.

Viscosity

Viscosity is a fluid’s resistance to flow. A fluid with a high viscosity (such as honey) is more resistant to flow versus a fluid with low viscosity (water).

The viscosity of different tailings varies. Thickened tailings and paste have a high viscosity, whereas iron ore tailings for example are usually more dilute.

Lachlan says that, generally, the lower the viscosity of the slurry, the higher the physical wear in a pipeline.

“If your carrier fluid is more viscous, towards the ‘toothpaste’ end of the spectrum, the fluid tends to carry the coarse particles around obstacles in the flow,” he says.

“Particles are less likely to impact upon the pipe surface as the viscosity goes up. As the viscosity increases, there’s less erosive wear.”

On the other hand, a dilute slurry, such as iron ore tailings, has a lower viscosity and therefore needs to be pumped at higher velocity to reduce settling.

Pumping at higher velocity has a downside though. It increases the velocity of solid particles hitting the walls of the pipe which in turn increases wear on the pipe walls. This means that bare carbon steel or HDPE lined pipe is typically not suitable for high velocity slurries.

Unlined carbon steel or HDPE lined pipe is typically not suitable for high velocity or abrasive slurries.

Get advice and data for a frustration-free pipeline

Your goal with a new slurry pipeline should be to design it right the first time, so it lasts the life of the project. The alternative is failure followed by downtime and expensive maintenance.

That’s why the true test of your pipeline project’s success comes in the months and years after. If you haven’t factored in the slurry properties, it could end up being a maintenance nightmare.

Lachlan says it pays to get expert guidance early on because slurries can vary greatly from the ore type to the type of processing in the plant.

“It’s likely that the operating conditions will change throughout the process life of a plant. An example of this is if the ore body or process conditions in the plant change.

“So, you need to design for a possible range of conditions and know the range of rheology as best you can.”

Conducting rheology testing, or slurry loop testing together with pipe design models will give you the most accurate data about how your slurry will behave, so you can iron out issues before they occur.

It pays to know what you’re pumping

Slurry rheology has a big impact on pipeline wear and performance.

Having a good understanding of this will help you design a better pipeline that will last the length of the project.

It pays to do in-depth analysis of the settling properties, Newtonian vs non-Newtonian behaviour, and viscosity of the slurry that your pipeline will transport.

It could be the difference between a pipeline that’s seen as a liability to the operation, or one that’s a valuable asset.

Get practical recommendations for your pipeline

Reach out to setup a call with a pipeline specialist. We'll give you clear recommendations and advice to help you with your piping specification, so you can confidently design a pipeline that lasts.

"*" indicates required fields