The slurry piping system is critical to whether that plant reliably works—or reliably fails.

If it’s done right, you look good, and everyone is happy.

We work with maintenance teams who deal with lithium slurry every day. They tell us how quickly its jagged, hard, sharp particles slice through slurry piping systems if they’re not up to the job.

So, to help share those lessons learned, we’ve compiled our top three principles from years of experience working in lithium processing:

1. Don’t cut costs in high wear areas

Lithium plants have extremely abrasive slurry. Large, jagged particles moving at high velocity will tear your slurry piping apart.

Sharp, abrasive lithium rock

It’s important to identify the highest wear areas of the plant to make sure you specify the right slurry piping for the job.

Rubber-lined piping is often seen as a cost-effective choice for new plant designs, but we have plenty of examples where it simply doesn’t last the distance in severe wear areas. And unfortunately, you end up with situations like this one.

For example, the Mt Marion plant suffered from persistent leaks in the rubber-lined pipe on their coarse classifier line. You can read the full case study here.

So, if you think rubber-lined steel isn’t going to be a durable enough option, what other choices are there?

In our experience, ceramic-lined mining hose is often a better fit. That’s because:

a. Ceramic tiles are durable

The tiles resist abrasion from sharp slurry because they absorb and dissipate impact from particles.

b. Mining hose has a dampening effect

When you combine the hard ceramic liner with the dampening effect of rubber mining hose, you get piping that absorbs particle impact, and also reduces shattering and debonding.

c. Wear locations are within your control

You can control the wear spots at the ends or in specific sections of the hose. Just one part of the hose might take a beating, while the rest of the hose is fine. In this case, you can customise the hose with ceramic tiles on only one section.

For example, you can tile the bottom quadrant of straight hose to manage abrasion or sliding bed wear, or the outer arcs on bends for erosion wear. If you’re not sure of the wear location, consider tiling the full 360° lining.

Ceramic-lined mining hose with one quarter of the internal surface tiled (left) or fully tiled (right).

d. Rubber elbows are flexible and easy to install

This means you need less precise design tolerances and will have an easier time fitting everything together during construction.

2. Valves take a beating: Use severe service shear gate valves

If someone suggests saving on costs with rubber-seated knife gate valves, rethink it. Let’s discuss this in more detail.

The problem with using rubber-seated knife gate valves

The problem here is twofold—the rubber seats, and the knife gate itself.

Rubber seats: In a lithium slurry line, the hard, sharp particles get stuck to the rubber seat as they pass through and will quickly tear chunks off. This causes leaks right away.

Knife gate: Because of the knife blade shape, sharp particles stick to the blade, get stuck in the crevice, and can tear the seat when the blade closes.

This video shows how hard, sharp lithium slurry can build up between the gate and rubber seats, causing damage.

It doesn’t matter what type of rubber you use, rubber-lined seats just aren’t durable enough under harsh lithium slurry conditions. So, how about polyurethane then?

PU valve seats aren’t necessarily ideal either

Some lithium sites have tried polyurethane seats and had mixed success. Because they have less elastomer, they wear better than rubber so are fine for lighter duty areas of the plant. However, they still aren’t a good choice for high wear slurry lines.

So, what works reliably with heavy duty, high wear lithium slurry?

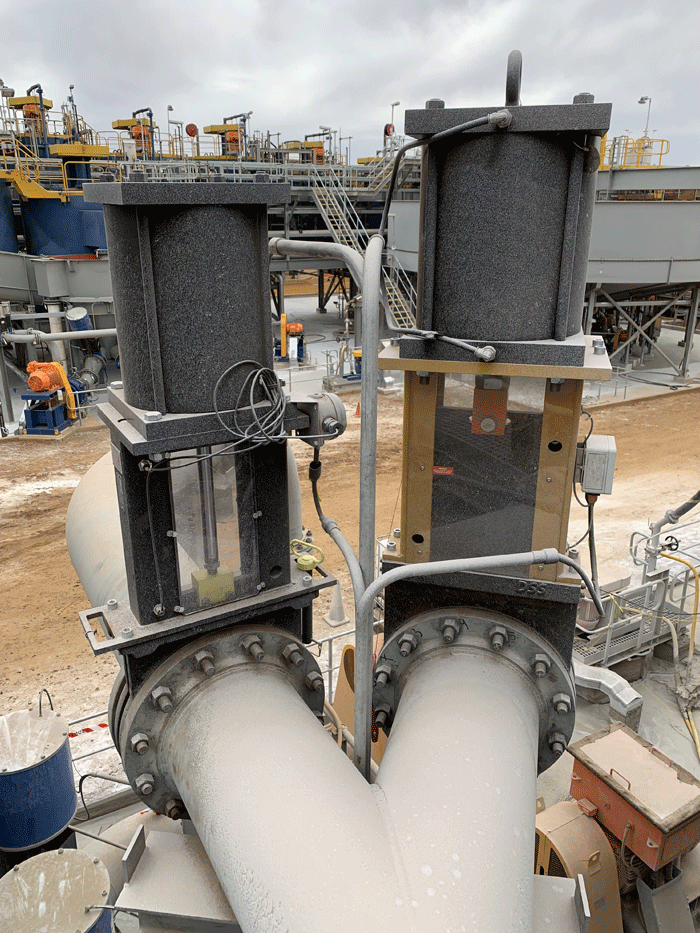

Metal seated severe service shear gate valves

Look for metal seated severe service shear gate valves. The metal seat will be durable enough to handle the sharp glass-like particles. The shear gate shape reduces the chance of particles getting stuck in the crevice when the gate closes. And you want to make sure your valves have guides to direct the seat straight down, without any movement.

Metal seated severe service shear gate valves installed at a lithium plant

3. Elbows take a hammering. Engineer for it.

You’ll often see localised wear on bends in slurry piping. When slurry reaches a bend at high velocity it creates high wear spots on the outer arc of bend where the impact is highest. This means localised wear spots and eventual pipe failure.

In our experience, rubber-lined steel spools and HDPE are not durable enough for bends with lithium slurry running through. We’ve seen this repeatedly.

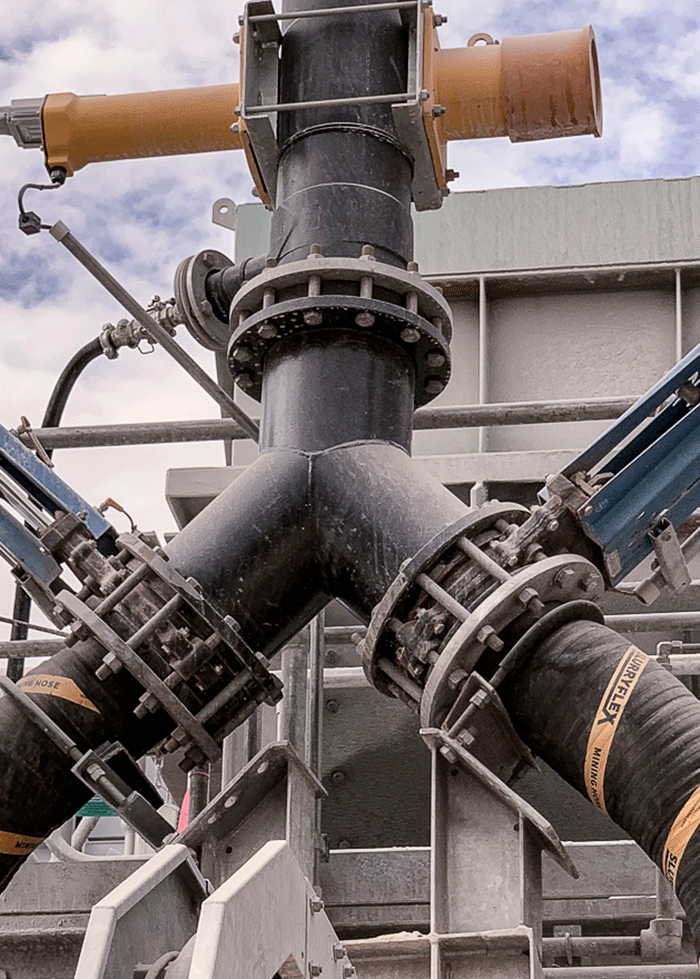

One example is Ngungaju plant where they found that their cyclone feed Y-piece kept getting torn to shreds by the sharp rock, and in the end, they replaced it with a polyurethane lined pipe, which solved the problem for good.

Example of polymer-lined Y-piece installed

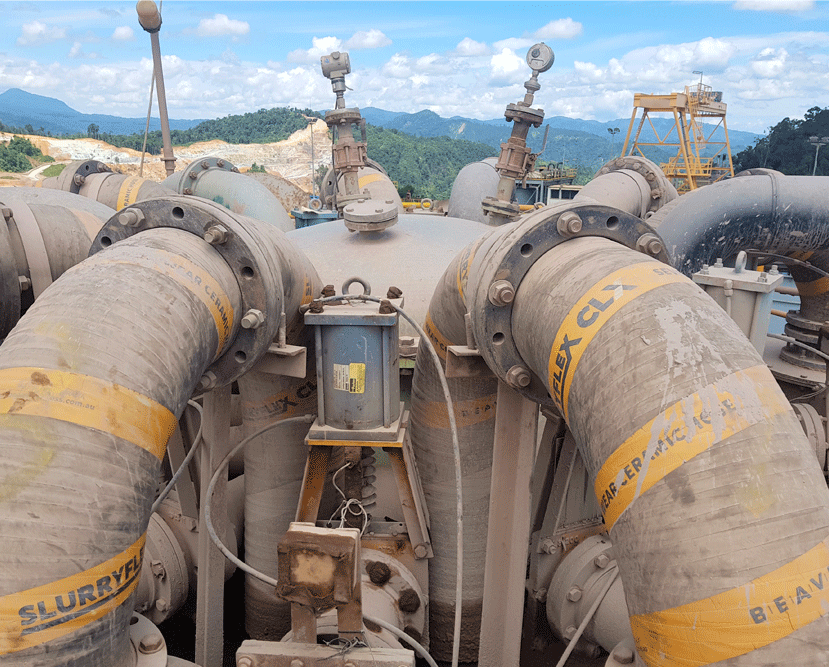

In small radius bends, like cyclone overflows, this wear is even more accelerated. According to our Piping Specialist Gavin Holland, ceramic-lined slurry hose is a better option here.

“It does two things to reduce wear in this situation. Ceramic tiles increase the wear life of the pipework by deflecting particles. At the same time, the rubber hose carcass absorbs and dissipates impact from high-velocity slurry,” says Gavin.

An example of this in practice is PT Agincourt’s Martabe mine. By upgrading from HDPE piping to mining hose, they’ve increased the lifespan of their cyclone piping by 900%. You can read the full story here.

Ceramic-lined mining hose installed on the cyclone overflow at Martabe mine increased lifespan by 9x.

Get the design right—first time

Our lithium customers have done the hard yards. They know what works and what doesn’t because they deal with the plant every day.

Learning from their experiences, you’ve got the benefit of hindsight to decide what will go into those high wear areas.

Your plant will sail through commissioning because you’ve managed those high wear areas of the slurry piping system.

Making those smart decisions now will pay dividends later—and your client will thank you for it too.