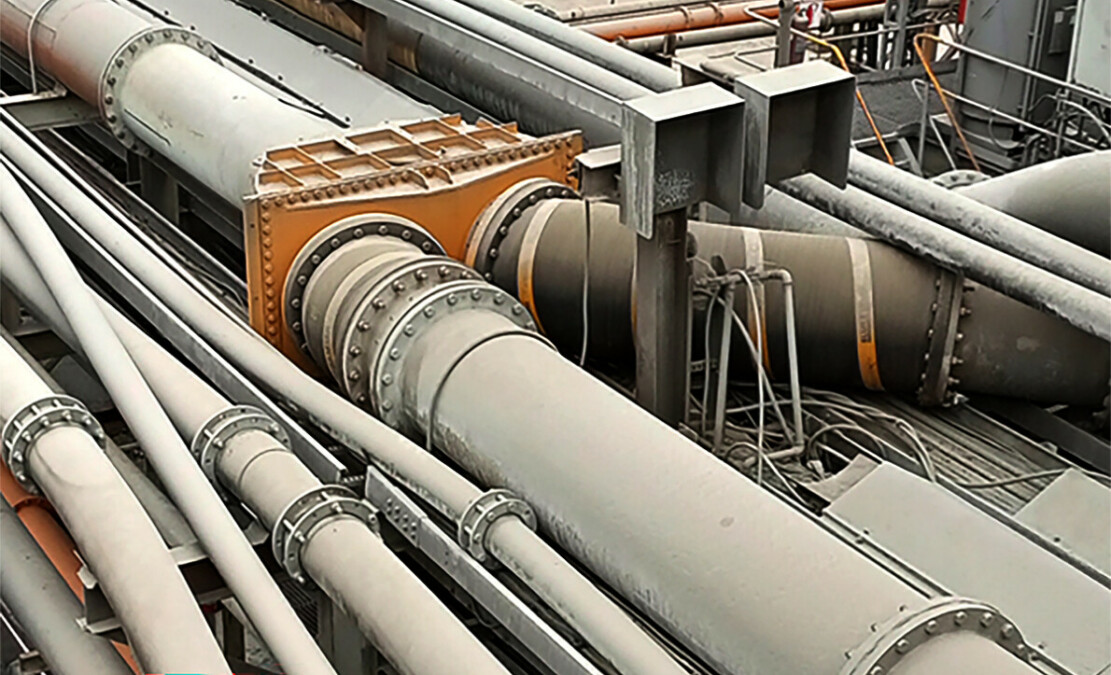

5x Wear Life on High Wear Slurry Lines – Kansanshi Copper-Gold Mine

The mechanical supervisor at First Quantum’s Kansanshi copper-gold mine was chasing the unicorn of slurry piping – “piping with longer life, easier installation, and easier removal.”

He was frustrated that the ceramic-lined steel pipes on their high-wear slurry lines were holing out and failing every six to nine months.

The process to remove and replace the DN600 pipes was arduous due to the size and location of the line. Each time they failed, the downtime cost hundreds of thousands of dollars in lost production.

There’s no ‘give’ with ceramic-lined steel pipe. There’s no tolerance for incorrect measurements. If there’s any misalignment during installation or in the tile liner, the slurry works its way under the tiles and holes out the steel substrate.

That’s why we recommended an option with more flexibility. Mining hose can better absorb and dissipate impact from high-velocity particles. It also has greater tolerance for twisting, stretching, and bending into place to correct misalignment.

The supervisor decided to trial one side of the feed with our Australian-made Slurryflex CLX mining hose against the lined steel pipe.

The results could not have been clearer.

Within months, the ceramic-lined piping had holed out and failed, while the Slurryflex CLX is still in place after two years.

That’s more than 5x the wear life.

It’s a big win for the supervisor and his team. He’s reduced costly downtime and put an end to constant bandaging and leaking pipes.

Client

Location Zambia

Commodity Copper & Gold

Challenge Highly Abrasive Wear

Outcome 5x Wear Life

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.