3x Longer Wear Life with Slurryflex Pre-Formed Mining Hose Reducer

This maintenance super was wading through knee-deep water in the process plant when he got in touch with us.

Fortunately, after re-engineering the slurry pump piping, this mine site in Western Australia turned it into a win—with a pre-formed mining hose reducer and no more leaks.

Location WA

Commodity Gold

Application Slurry pump suction

Increased wear life 3x

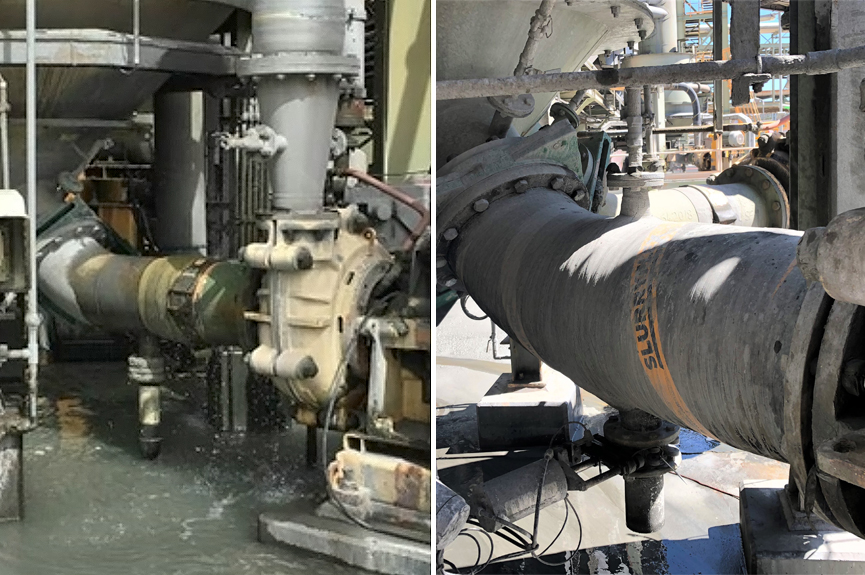

Previously, they used two rigid steel spools attached to the pump with a Straub coupling (pictured left). But the rubber-lined steel wasn’t durable enough for the highly abrasive slurry.

Also, the three-piece arrangement wasn’t reliable—the pump vibration caused it to misalign, leak continually, and need replacement in less than a year.

They decided to try our Slurryflex SD-Series mining hose reducer (pictured right), which we custom made in one piece with a pre-formed bend at one end to fit perfectly. It reduces noise and vibration and is more durable.

When we last checked, it had been running for three years and was still going strong: that’s more than 3x the wear life.

The maintenance team can ‘set and forget’ the spool now, and they no longer need a wetsuit to maintain the plant.

Related projects

How Roy Hill Solved Costly Unplanned Piping Maintenance for Good

WA Lithium Mine get 12x Longer Wear Life in Slurry Control Valves

8x Longer Lifespan for Cyclone Overflow Piping at FMG Solomon Mine

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.