First Quantum Cobre Copper Mine – Slurryflex Flexible Mining Hose

Three years ago, First Quantum’s Cobre copper mine decided to upgrade their pontoon pump hoses. Three years on, they’ve had reliability wins, improved safety, and the new hoses haven’t needed replacing.

In 2019, a senior mechanical engineer at the Panama mine emailed us because he was worried about a hose failure that could impact water supply to his processing plant.

“We’ve had a failure on a mining hose supplied by another supplier,” he said.

He explained they had 16x DN600 hoses connected to pumps on floating barges and asked us to figure out why they failed.

The old hoses were already leaking, so catastrophic failure was imminent. He needed a quick solution.

The problem was clear: they’d correctly chosen flexible mining hose to allow for movement on the pontoon. But, the supplied end connections weren’t suitable and had torn away from the hose ends.

We recommended building integral heavy duty spigots into the ends of new Slurryflex mining hoses to avoid end connections being a weak point.

We staggered production to let him replace the most damaged hoses first. The first 4 were hand made and shipped from Brisbane urgently.

Three years on, the engineer says: “The Slurryflex hoses are still installed and haven’t leaked once from the day they were installed.”

We’re happy to help solve his problem and see our Australian made hoses used on a Latin American mine site.

Client

Year 2019

Location Panama

Benefit Improved safety

Outcome Less downtime

Wear life 3 years+

Related projects

DeGrussa Copper Mine – Complete Tailings Storage Solution

Kanmantoo Copper Plant Conversion – SPI Package and Actuated Valves

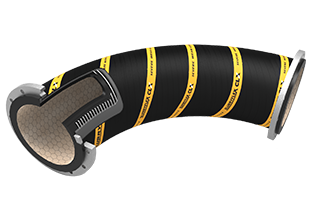

Slurryflex CLX XC-Series Pre-Formed Bend Ceramic Hose

A ceramic-lined rubber mining hose manufactured in a custom-specified shape for severe slurry applications.

Slurryflex CLX XE-Series Y-Piece/Lateral/Tee Ceramic Hose

A ceramic-lined rubber mining hose used to connect one pipeline to two others and vice versa in highly severe slurry applications.

Slurryflex SF-Series Superflex Hard-Wall Mining Hose

A highly flexible mining hose that can achieve a very tight bend radius, used in slurry applications.

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.