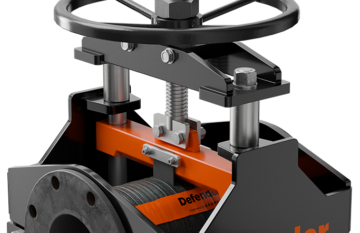

Valve reliability made simple

Imagine never worrying about slurry valve failures again. Built with heavy duty materials and precision engineered components, Defender valves outlast and outperform standard slurry valves. No more rushed repairs. No more unexpected shutdowns.

Don’t let a single valve compromise your entire plant

Your plant's efficiency shouldn't hinge on unreliable valves. Defender valves are engineered from scratch for tough slurry. It's a simple upgrade that boosts uptime and process control across your plant.

Engineered. Tested. Proven in the field.

Struggling with harsh slurry conditions? We've engineered Defender valves to thrive in the most demanding environments to resist wear, corrosion and erosion.

How?

The result? The new pinch valves last over 18 months and easily make it to multiple shutdowns. That’s 12x better wear life than the diaphragm valves.

Custom built for your slurry

Recurring valve issues are often caused by using outdated valve designs not up to the challenge of harsh slurry conditions.

These valves just aren’t suitable for the relenteless wear and tear of a modern processing plant. Defender valves can be customised to match your slurry, so the upgrade will last. That way you can focus on optimising your plant, not firefighting valve issues.

Upgrade to reliable valve performance

Without the right valves, it's a constant battle to maintain flow, prevent leaks, and avoid unplanned downtime.

We'll assess your current pain points, recommend optimal valve placements, and custom manufacture the right valves to eliminate chronic failures.

Upgrade to valves that handle extreme wear, resist corrosion, and maintain tight seals – even in your most demanding applications.

How we help you choose the right valves:

Proven on the world’s toughest mine sites

Talk to a Defender valve specialist

Tired of replacing valves in your plant? Our specialists will help you unlock easy reliability wins with Defender valves.