The challenge

Unplanned shutdowns were a costly exercise at Martabe’s processing plant.

HDPE piping in the cyclone overflow was failing after only 2,100 operating hours, or three months of service, causing stops in production to make repairs.

Martabe’s plant reliability engineer was eager to find a way to extend the lifespan of the pipework to meet the mine’s annual production target.

He knew continuing to replace the worn HDPE spools with new HDPE wasn’t a sustainable option long-term. But he needed a solution that was going be ready in time for the next shutdown – just six weeks away.

Our analysis

The engineer asked if we could send our piping experts to site to examine the cyclone overflow and provide an audit report.

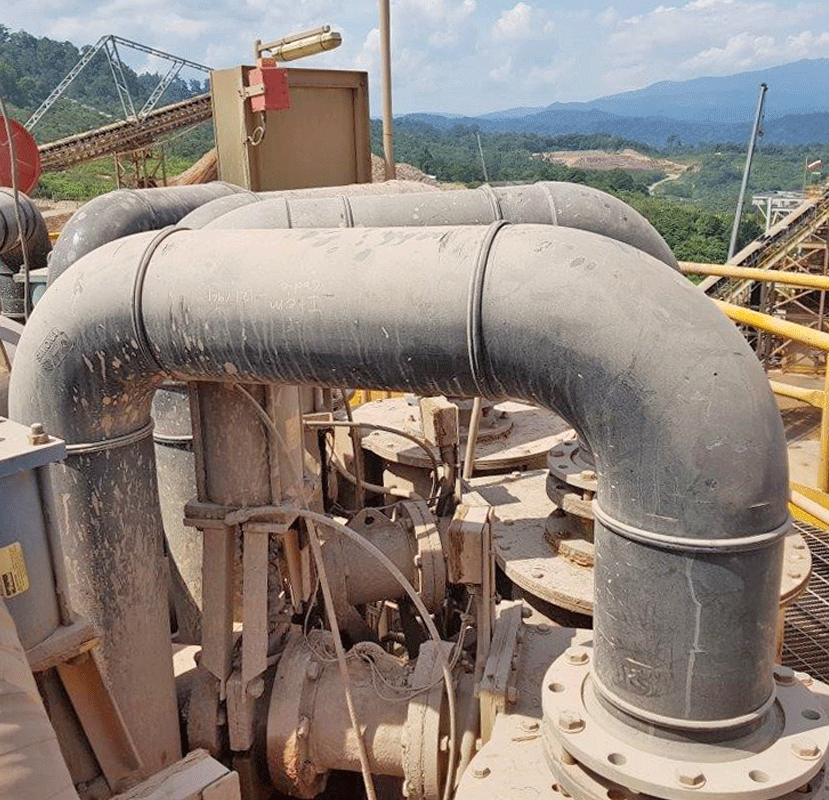

We found that a combination of HDPE straights and bends were welded together to connect to the overflow system. With a small area to connect the pipework, the radius of the HDPE bends was very tight.

The tight radius was increasing the impingement wear from the small, highly abrasive particles. And this was resulting in excessive localised wear in the bends.

The HDPE overflow pipes were wearing right on the outlet flange, where slurry flow is most turbulent exiting the cyclone. We noticed that the existing design was using a one-piece HDPE pipe, meaning the maintenance team needed to dispose of the entire spool even though only the flange outlet was worn.

“We know hydrocyclones are a challenging area in any processing plant.

Short-radius bends and abrasive slurry cause aggressive wear on pipework.

They’re prone to leaks and wear, and as a critical area in the plant, it’s essential to get the piping right to keep things moving.”

Gavin Holland

Project Manager, Beaver Process Equipment

Our recommendations

1. Re-engineer the bends

To overcome the localised wear on the bends, we proposed redesigning the pipe geometry to a longer radius. This creates a more sweeping arc to reduce turbulence and wear.

2. Improve impact absorption and vibration

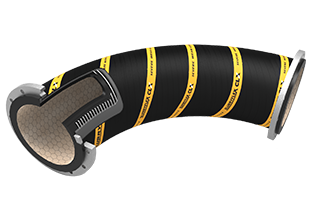

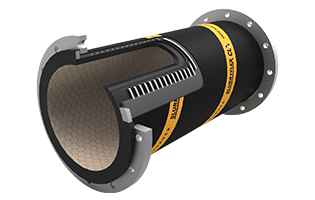

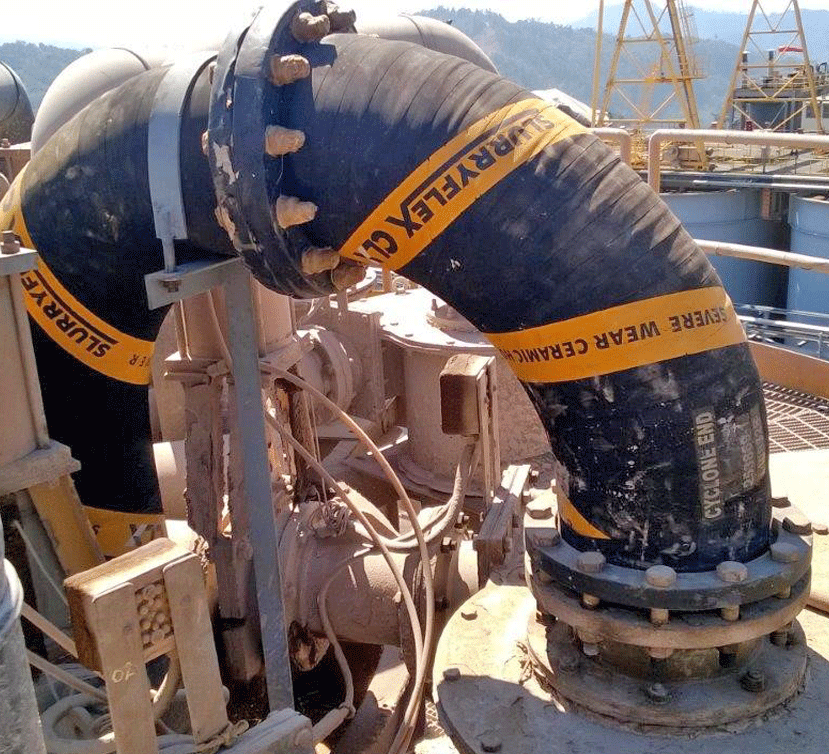

We recommended that the team address the issue of impact wear and better manage vibration. In our experience, switching from HDPE piping to Slurryflex CLX mining hose helps achieve this. Because CLX has ceramic tiles heat embedded in the rubber, it can handle highly abrasive slurry transport, and also offers all the impact and flexibility benefits of a hose.

3. Reduce excessive wear on flanges

To tackle the localised flange wear issue, we suggested using a two-piece mining hose set-up.

This would allow the team to simply remove the worn elbow and replace with another, and not replace both hoses.

We recommended using a 12mm-thick Slurryflex CLX ceramic-lined rubber mining hose for this purpose.

The Grade A rubber provides long term resistance to abrasion, cutting, and tearing.

The engineer agreed with our recommendations and our Brisbane team got to work custom engineering and manufacturing a complete cluster of cyclone assemblies to match the new geometry.

The outcome

We air-freighted the bore-matched bends and delivered them in full to the remote Indonesian site within four weeks – two weeks ahead of shutdown.

For the engineer, the spools are now easily reaching bi-annual scheduled shutdowns.

The new bends have been operating for 17,000 hours and are still going strong.

That’s over nine times the lifespan of the previous HDPE pipes – plus it’s put an end to bandage jobs and unplanned shutdowns.

Lifespan 9x longer than HDPE spools

Piping performance 17,000 operating hours

Durability No more bandaging leaks

Custom made Engineered to specification