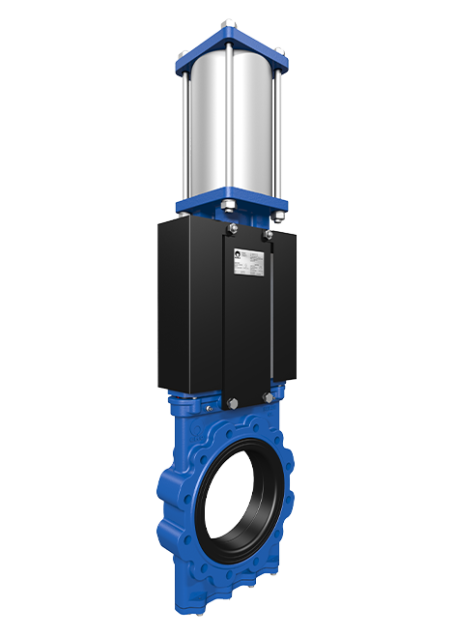

The CMO GL Slurry Knife Gate Valve has a monobloc reinforced cast iron body to ensure unobstructed flow and a watertight seal for complete fluid isolation. This valve doesn’t produce cavities when it’s open, eliminating turbulence in the fluid flow. A full port allows high flow rates with low pressure drop.

A push-through seat contains two opposing resilient rubber sleeves that seal against each other when the valve is open. Mounting this valve between two connection flanges compresses the sleeves which creates seal-tight isolation when the knife gate closes. No metal part of the valve comes into contact with the slurry. This design stops solids from building up, as there is no seat cavity which could prevent the gate from fully closing.

Available in wear-resistant natural or synthetic rubber, the sleeves enclose an integrally moulded metal ring that maintains the round shape and helps resist compression or stretching.

The CMO GL Slurry Knife Gate Valve is suitable for transporting highly abrasive media with up to 50% solids concentration.

Technical specifications

Brand

Model

Size range

Contact us for bigger sizes

Pressure class

6 bar (DN700–900)

4 bar (DN1000–1500)

End connections

Actuator options

Gear operated

Pneumatic

Hydraulic

Electric

Material specifications

Body

On request: A216WCB carbon steel and stainless steel alloys (AISI 316 Ti, Duplex 254 SMO, Uranus B6, Ni-Resist, Ductile Ni-Resist)

Gate

On request: Duplex SAF 2205 and 2507, stainless Steel 17-4PH, and other materials, coatings, and finishes

Seat and max temperature

Viton (210°C)