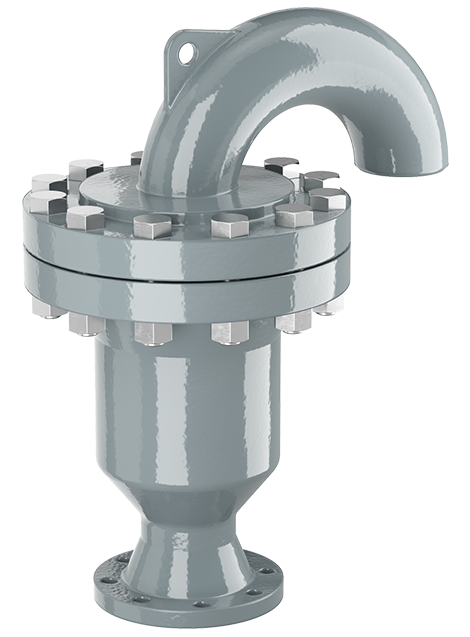

The Beaver AB Series Air Valve is a combination air valve with two main functions: removing large amounts of air during the filling process and admitting air into the pipeline while it’s being emptied.

For the body lining, this custom-built valve uses Slurryflex Grade-A rubber, a specialty rubber compound that exhibits excellent resilience against wear and abrasion. The lining can be further customised with other materials, including custom-engineered polymer, to further boost abrasion resistance.

The Beaver AB Series Air Valve is specifically engineered for demanding slurry applications and other severe services involving undissolved solids.

Technical specifications

Brand

Beaver

Model

AB150 (Class 150)

AB300 (Class 300)

AB300 (Class 300)

Size range

DN25–300 (1–12”)

Pressure class

Class 150

Class 300

Class 300

Temperature range

-29°C to +80°C

End connections

Flanged

Design and manufacture

ASME B31.3

ASME B16.34

ASME B16.34

Testing and inspection

API 598

Material specifications

Body and bonnet

Carbon steel

Stainless steel

Duplex and super duplex stainless steel

Exotic alloy

Stainless steel

Duplex and super duplex stainless steel

Exotic alloy

Body and bonnet coating

Multi-pack polyurethane

Multi-pack modified epoxy

Custom options

Multi-pack modified epoxy

Custom options

Body lining

Slurryflex Grade A rubber

Polyurethane

NBR

Bromobutyl

Custom-engineered polymer

Polyurethane

NBR

Bromobutyl

Custom-engineered polymer

Float

HDPE

Nitrile-coated aluminium or stainless steel

Bromobutyl-coated aluminium custom engineered polymer

Urethane-coated aluminium or stainless steel

Nitrile-coated aluminium or stainless steel

Bromobutyl-coated aluminium custom engineered polymer

Urethane-coated aluminium or stainless steel

Seal

Wear-resistant natural rubber

Urethane

Nitrile

Bromobutyl

Custom-engineered polymer

Urethane

Nitrile

Bromobutyl

Custom-engineered polymer

Gasket

NBR