Argyle Diamond Mine – Ceramic-Lined Mining Hose Upgrade

In 2015, the maintenance engineer at Rio Tinto’s Argyle diamond mine approached us to fix leaking and fast-wearing pipe work on their de-grit line. They’d spent over 1,000 man-hours repairing, maintaining, and sealing the pipes. Despite this, the pipes only lasted 3-6 months, causing unplanned shutdowns.

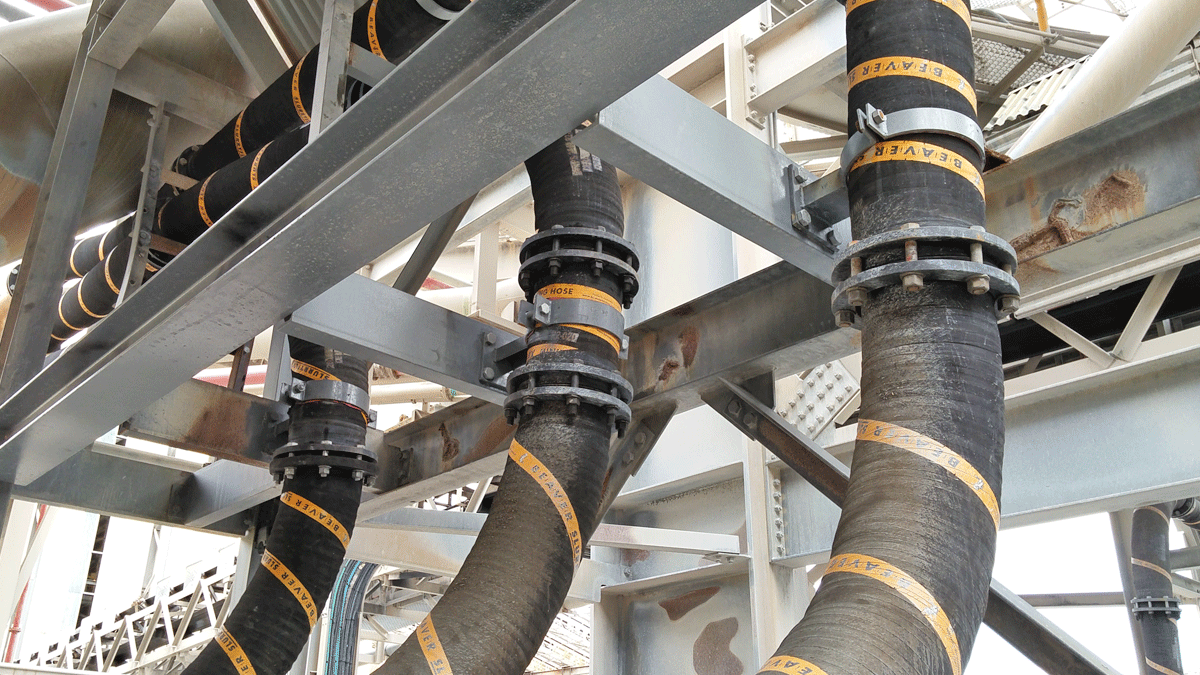

We completed a site audit with the maintenance team and recommended changing to Slurryflex CLX ceramic-lined mining hose. Rubber hose with a severe-wear ceramic lining offers better impact absorption and flexibility and is long-lasting in abrasive conditions.

This has been a game-changer for the site—it increased the lifespan of the line spools from 3-6 months to 5 years. This has eliminated unscheduled breakdowns and safety issues caused by leaking pipes.

Client

Year 2015

Project size $0.1M

Location WA

Related projects

How Roy Hill Solved Costly Unplanned Piping Maintenance for Good

WA Lithium Mine get 12x Longer Wear Life in Slurry Control Valves

8x Longer Lifespan for Cyclone Overflow Piping at FMG Solomon Mine

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.