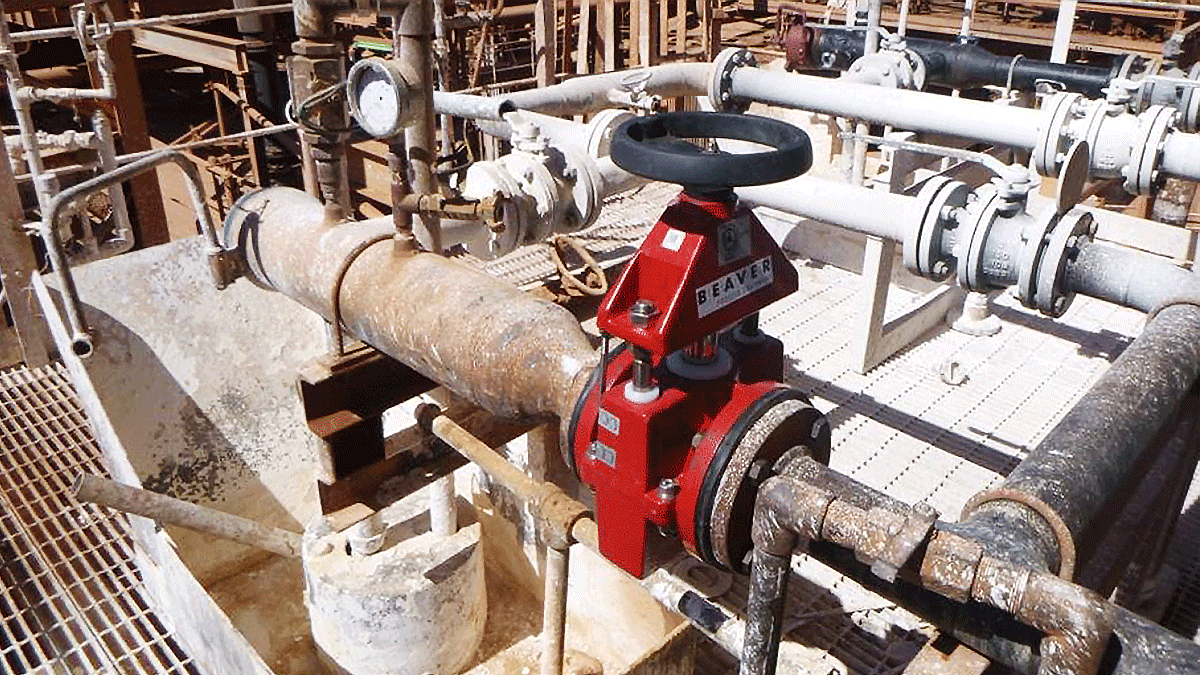

Alcoa Alumina Refinery – Custom Pinch Valve for Pigging Station

In 2021, the mechanical engineer at Alcoa Pinjarra’s alumina refinery was trying to solve a long-standing issue with valves seizing on the lime circuit’s pigging station. This was making it difficult for the technicians open and close the valves and clean the lines.

We recommended they trial pinch valves. The full port design of pinch valves allows the pig to travel through the valve. Plus, the elastomer wear-resistant sleeve is the only part of the valve that contacts the fluid. This reduces the risk of the seizing and reduces operating fatigue.

This was a big win for the Pinjarra team. The valve has lasted twice as long as its predecessors, with plans underway to replace all the valves on the line with pinch valves.

Client

Alcoa Client Logo

Year 2021

Project size $0.1M

Location WA

Related content

Nullagine Gold Mine – Valve Specification and Supply for New Plant

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.